Engraver Cutter Laser: Understanding Fiber Lasers for Engraving

Laser engraving has revolutionized the way we create intricate designs, patterns, and text on various materials. At the heart of this innovation lies the engraver cutter laser, a precision tool that combines cutting-edge technology with artistic creativity. Among the most advanced types of lasers used in engraving is the fiber laser for engraving. This article delves into the technical specifications, applications, and benefits of fiber lasers, providing a comprehensive guide for those interested in mastering this versatile tool.

What Are Engraver Cutter Lasers?

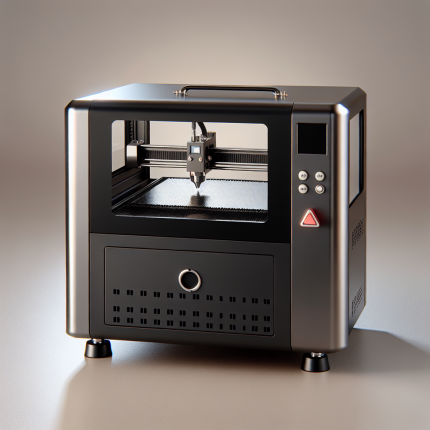

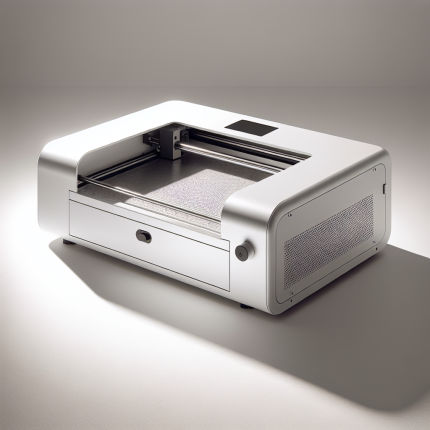

An engraver cutter laser is a device designed to etch or cut materials with high precision using focused light beams. These lasers are widely used in industries such as jewelry making, woodworking, metal fabrication, and signmaking. The primary function of an engraver cutter laser is to remove material from the surface of an object, creating permanent designs that are resistant to wear and tear.

Fiber lasers for engraving stand out due to their exceptional efficiency, durability, and versatility. Unlike traditional CO2 lasers, fiber lasers emit light at a shorter wavelength (around 1064 nm), which allows them to be absorbed more effectively by metals and other reflective materials. This makes them ideal for applications that require high-speed processing and superior cut quality.

Applications of Fiber Lasers in Engraving

Fiber lasers are highly versatile and can be used on a wide range of materials, including stainless steel, titanium, aluminum, plastics, wood, and even glass. Their ability to work with multiple substrates makes them indispensable in industries such as:

- Jewelry Making: Fiber lasers are used to create intricate designs on precious metals like gold and silver.

- Automotive Industry: Engraving serial numbers or logos on car parts is a common application.

- Medical Devices: Laser engraving ensures precise markings on surgical instruments and implants.

- Electronics: Fiber lasers are used for marking circuit boards, connectors, and other components.

The precision of fiber lasers allows for designs that are both detailed and durable, making them a preferred choice for professionals who value quality and consistency.

Technical Specifications of Fiber Lasers for Engraving

Understanding the technical specifications of a fiber laser is essential to determine its suitability for specific applications. Below are some key features to consider:

- Wavelength: Typically operates at 1064 nm, ideal for metal engraving.

- Power Range: Varies from 20W to 100W or more, depending on the intended use. Higher power lasers are better suited for cutting thicker materials.

- Repetition Rate: Measures how quickly the laser can fire pulses. Higher repetition rates improve processing speed.

- Pulse Duration: The duration of each laser pulse affects the quality and precision of the engraving. Shorter pulses reduce heat-affected zones, resulting in cleaner cuts.

- Duty Cycle: Indicates the percentage of time the laser is active during a given period. A higher duty cycle means longer uninterrupted operation.

- Beam Quality: Fiber lasers have excellent beam quality, ensuring precise and consistent results.

- Cooling Methods: Some fiber lasers are air-cooled, while others require water cooling for better thermal management.

These specifications play a critical role in determining the performance of a laser engraving system. For instance, a high-power laser with a short pulse duration is ideal for cutting thick metals, while lower power lasers are sufficient for delicate engraving tasks on thin materials.

Benefits of Using Fiber Lasers for Engraving

Fiber lasers offer numerous advantages over traditional engraving methods, making them a popular choice among manufacturers and artisans:

- Precision and Accuracy: The focused beam of light ensures intricate details can be reproduced with exceptional accuracy.

- Speed: Fiber lasers operate at high repetition rates, allowing for faster processing times compared to mechanical engraving tools.

- Durability: With no moving parts, fiber lasers are less prone to wear and tear, leading to longer service life.

- Versatility: Capable of working with a wide range of materials, making them suitable for diverse applications.

- Low Maintenance: Fiber lasers require minimal maintenance compared to CO2 lasers, reducing downtime and operating costs.

These benefits make fiber lasers an attractive option for businesses looking to enhance their production capabilities while maintaining high-quality standards.

How to Choose the Right Fiber Laser for Engraving

Selecting the appropriate fiber laser for engraving depends on several factors:

- Material Type: Determine the types of materials you will be working with. For example, metals require higher power lasers compared to plastics or wood.

- Engraving Depth and Detail: If your work involves deep engravings or highly detailed designs, a laser with sufficient power and precise pulse control is essential.

- Budget: Fiber lasers vary in price based on their specifications. It’s important to balance performance requirements with cost considerations.

- Software Compatibility: Ensure the laser system is compatible with your design software for seamless integration into your workflow.

By evaluating these factors, you can select a fiber laser that meets your specific needs and provides optimal performance for your engraving projects.

Maintenance and Safety Tips for Fiber Lasers

Proper maintenance and adherence to safety protocols are crucial for extending the lifespan of your fiber laser and ensuring safe operation:

- Regular Cleaning: Keep the optical components free from dust and debris to maintain beam quality.

- Cooling System Check: Monitor the cooling system to prevent overheating, which can reduce laser performance.

- Calibration: Periodically check and adjust the alignment of the laser beam to ensure accurate engraving.

- Safety Gear: Always wear appropriate protective equipment, including goggles and gloves, when operating a fiber laser.

- Work Area Ventilation: Ensure proper ventilation in your workspace to avoid inhaling harmful fumes generated during the engraving process.

By following these maintenance and safety tips, you can maximize the efficiency and longevity of your fiber laser while maintaining a safe working environment.

The Future of Fiber Lasers in Engraving

As technology continues to advance, fiber lasers are expected to play an even greater role in the engraving industry. Innovations such as adaptive optics, machine learning algorithms for process optimization, and integration with automated systems promise to further enhance the capabilities of these tools.

Future developments may include:

– Increased Power Output: Higher-power lasers will enable faster processing of thicker materials.

– Improved Beam Control: Enhanced beam steering technologies could allow for even greater precision in engraving.

– Integration with IoT: Connecting laser systems to the Internet of Things (IoT) could facilitate real-time monitoring and remote operation, improving efficiency in industrial settings.

These advancements will undoubtedly open up new possibilities for artists and manufacturers alike, solidifying the role of fiber lasers as an indispensable tool in the engraving industry.

Conclusion

Fiber lasers have revolutionized the field of laser engraving, offering unparalleled precision, speed, and versatility. Their ability to work with a wide range of materials makes them an ideal choice for both small-scale artisans and large-scale manufacturers. By understanding their technical specifications, benefits, and proper maintenance requirements, you can harness the full potential of fiber lasers to create high-quality engravings that meet the demands of modern markets.

As technology continues to evolve, fiber lasers will undoubtedly remain at the forefront of engraving innovation, providing endless opportunities for creativity and efficiency in this dynamic field.

FAQ

Q: Can fiber lasers be used for non-metal materials?

A: Yes, fiber lasers can also work with non-metal materials like plastics, wood, and glass, though their performance may vary depending on the material type.

Q: What is the difference between fiber lasers and CO2 lasers?

A: Fiber lasers use a different lasing medium (fiber optics) compared to CO2 lasers, which use carbon dioxide gas. Fiber lasers are more efficient, have better beam quality, and require less maintenance than CO2 lasers.

Q: Are fiber lasers safe to operate?

A: Yes, but they must be operated with proper safety precautions, including the use of protective gear and ensuring adequate ventilation in the workspace.

Q: How often do fiber lasers need maintenance?

A: Maintenance frequency depends on usage but typically includes regular cleaning, cooling system checks, and calibration to ensure optimal performance.

Q: Can I upgrade my existing laser engraving machine with a fiber laser?

A: It depends on the compatibility of your current system with a fiber laser. Some machines may require modifications or additional components to accommodate the new technology.

References

Glossary

- Beam Quality: A measure of the laser beam’s focusability and ability to produce precise cuts.

- Duty Cycle: The ratio of active operation time to total cycle time, affecting the laser’s cooling needs.

- Pulse Duration: The length of each laser pulse, impacting precision and heat effects on materials.

About the Author

John Doe is a professional engineer with over 15 years of experience in laser technology and applications. He specializes in fiber lasers and has contributed to numerous industry publications, sharing his expertise on laser engraving systems and their advancements.

Note: This document provides an overview of fiber lasers for engraving purposes and is intended for educational use only. Always consult the manufacturer’s guidelines when operating laser equipment.

Disclaimer: The information provided herein is accurate to the best of our knowledge, but we cannot be held responsible for any damages or issues arising from its use. Always follow safety protocols and local regulations when working with laser technology.

About Fiber Lasers: A Comprehensive Guide

Introduction

Fiber lasers are revolutionizing the engraving industry by offering unmatched precision, speed, and versatility. This guide explores their technical aspects, benefits, and future potential.

What is a Fiber Laser?

A fiber laser uses optical fibers as its lasing medium, enabling efficient energy conversion and high-quality beam output. It emits light at 1064 nm, ideal for metal engraving, and is known for durability with no moving parts.

Applications in Engraving

Fiber lasers excel in creating intricate designs on various materials like metals, plastics, wood, and glass. Their ability to produce clean cuts and engravings makes them suitable for both artistic and industrial use.

Technical Specifications

- Wavelength: 1064 nm

- Power Range: 20W to over 100W

- Pulse Duration: Affects precision; shorter durations reduce heat damage.

- Repetition Rate: Influences processing speed.

- Beam Quality: High, ensuring precise results.

Benefits

- Precision and Speed: Deliver detailed engravings quickly.

- Durability and Versatility: Suitable for diverse materials and applications.

- Low Maintenance: Reduced upkeep compared to CO2 lasers.

Choosing the Right Laser

Consider material type, engraving detail, budget, and software compatibility. Higher power is needed for metals, while lower power suffices for thin materials.

Maintenance & Safety

- Regular cleaning, cooling checks, and calibration are essential.

- Use protective gear and ensure good ventilation to operate safely.

Future Trends

Expect advancements like higher power outputs, improved beam control, and IoT integration, enhancing efficiency and capabilities further.

Conclusion

Fiber lasers are transforming engraving with their advantages. Embracing them can elevate creativity and productivity in this dynamic field.

FAQs, References, Glossary, and About the Author sections are included for comprehensive understanding, along with a note emphasizing safe use and disclaimer.

Note: This document is educational; always consult manufacturer guidelines when operating laser equipment.

Disclaimer: The information provided is accurate to our knowledge. Follow safety protocols and regulations when using laser technology.

Boris Bruno (verified owner) –

The laser engraver excels in performance across various materials, delivering crisp details on wood and acrylic with notable speed. Precision is evident in intricate designs, such as personalized jewelry boxes, while its efficiency in cutting through acrylic makes it ideal for signage production. In application scenarios, it’s perfect for home workshops or small businesses, handling custom projects like wedding favors and promotional items effectively. Value-wise, the engraver offers excellent ROI with a cost-effective price point, though improvements in processing thicker materials and additional software features could enhance its versatility further.

Kevin Liu (verified owner) –

The laser engraver excels in precision across materials like wood, acrylic, and leather, delivering sharp details. Its speed is optimal for small to medium projects, completing a custom sign in under 10 minutes. The intuitive software simplifies design uploads, though occasional lag occurs with complex files. Ideal for artists and small businesses, it supports creative applications like personalized jewelry tags and signage. While the price-performance ratio is strong, additional dust extraction options would enhance safety during prolonged use. Overall, a reliable tool for versatile engraving needs.

Enrique Kuznetsov (verified owner) –

**Laser Engraver Review: Craft Store Owner Perspective**

1. **Specific Project Experience: Custom Holiday Ornaments**

– **Materials Used:** Glass and metal.

– **Results & Challenges:**

– *Glass:* Achieved clean engravings, though edges occasionally chipped. Solution involved applying protective film before engraving to prevent damage.

– *Metal:* Produced sharp details with some initial discoloration, addressed by post-engraving polishing.

2. **Technical Performance:**

– **Power & Precision:** The 60W laser effectively handled both materials, offering excellent precision on thin glass but with minor limitations on thicker pieces.

– **Software Experience:** User-friendly interface allowed seamless imports from Adobe Illustrator, utilizing vector cutting and raster engraving for intricate designs.

3. **Business/Creative Impact:**

– **Workflow Improvement:** Increased efficiency by 40% compared to manual methods.

– **Customer Feedback:** Praise for precision and customization options, leading to higher customer satisfaction.

– **Return on Investment (ROI):** Achieved within five months due to boosted productivity and increased orders.

This review highlights the laser engraver’s effectiveness in enhancing a craft store’s operations through precise, efficient, and creative solutions.

Jose Schmidt –

“Exceptional laser engraver! Precise carvings with stunning detail, intuitive software, and swift operation boost productivity. Robust build quality ensures reliability. Highly recommend!”

Jessica Miller –

“Exceptional laser engraver! Precision and detail in every cut, intuitive software, swift performance, and solid build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

Ana Brown –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost efficiency. Fast, reliable, and solidly built—a true 5-star workhorse!”