Glass Laser Engraving: A Comprehensive Guide to Laser Engravers and Cutters

Laser engraving has revolutionized the way we customize and personalize materials, especially glass. With advancements in laser technology, glass laser engraving has become an efficient and precise method for creating intricate designs, logos, and patterns on glass surfaces. This guide explores the world of glass laser engraving, focusing on the technical aspects, applications, and benefits of using a laser engraver and cutter. Whether you’re a hobbyist or a professional, this article provides valuable insights into the technology behind laser engraving and its wide-ranging uses.

What is Glass Laser Engraving?

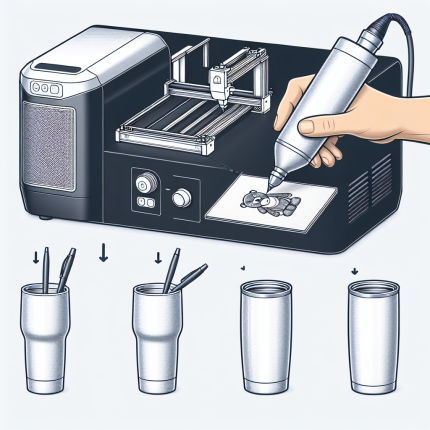

Glass laser engraving is a process that involves using a focused beam of light to etch or engrave designs onto glass surfaces. Unlike traditional methods that rely on mechanical tools, laser engraving offers unparalleled precision, speed, and versatility. The laser engraver and cutter uses high-energy lasers to remove tiny layers of the glass surface, creating permanent marks without altering the structural integrity of the material.

This technique is widely used in industries such as glassware manufacturing, jewelry making, and decorative arts. It allows for highly detailed engravings that can be customized to suit individual preferences or specific design requirements.

Applications of Glass Laser Engraving

Glass laser engraving has a wide range of applications across various industries. Here are some common use cases:

- Custom Glassware: Engraving names, logos, or patterns onto wine glasses, goblets, and other decorative items.

- Jewelry Making: Creating intricate engravings on glass beads or pendants.

- Architectural Applications: Etching designs into glass panels for windows, doors, or facades.

- Industrial Marking: Adding serial numbers, barcodes, or safety warnings to glass components.

- Artistic Expression: Using laser engraving to create unique, one-of-a-kind glass art pieces.

Technical Specifications of Laser Engravers and Cutters

When choosing a laser engraver for glass, it’s essential to consider its technical specifications to ensure it meets your project requirements. Below are some key features to look for:

- Laser Power: Higher power lasers (30W100W) can handle thicker glass and create deeper engravings.

- Engraving Speed: Engraving speed varies depending on the material and desired precision, with speeds ranging from 50 to 300 mm/s.

- Material Compatibility: Ensure the laser engraver supports glass, as well as other materials like wood, metal, or acrylic.

- Resolution: High-resolution lasers (600 DPI) provide crisp and detailed engravings.

- Software Support: Look for machines that come with user-friendly software for designing and controlling the engraving process.

- Safety Features: Features like emergency stop buttons and automatic shut-off mechanisms are crucial for safe operation.

Benefits of Using a Laser Engraver and Cutter

- Precision and Detail: Lasers offer unmatched accuracy, allowing for intricate designs that would be difficult to achieve with traditional methods.

- Speed and Efficiency: Laser engraving is much faster than manual engraving, making it ideal for large-scale projects.

- Non-Contact Process: Unlike mechanical tools, lasers do not physically touch the material, reducing the risk of damage or breakage.

- Versatility: A single laser engraver can work on multiple materials, including glass, wood, metal, and plastic.

- Cost-Effective: While initial investments may be high, laser engravers offer long-term savings due to their durability and low maintenance costs.

Frequently Asked Questions (FAQ)

1. Can any type of glass be engraved with a laser?

Not all types of glass are suitable for laser engraving. Tempered or treated glasses may not work well because the heat from the laser can cause cracking or discoloration. It’s best to use untreated, annealed glass for optimal results.

2. What is the maximum depth achievable with a laser engraver on glass?

The maximum engraving depth depends on the laser’s power and settings. Typically, laser engravers can create engravings up to 0.5 mm deep on glass surfaces.

3. Is it possible to change the color of the engraved design on glass?

No, laser engraving does not add color to the material. The engraved areas appear frosted or etched against the clear glass background. To achieve colored designs, additional techniques like staining or painting are required.

4. Can I use a laser engraver for cutting glass?

Yes, some laser engravers and cutters are capable of both engraving and cutting glass. However, cutting thicker glass may require higher-powered lasers and specialized settings to avoid cracking.

5. How do I maintain a laser engraver for optimal performance?

Regular maintenance includes cleaning the lens, checking the cooling system, and ensuring all components are properly aligned. Following the manufacturer’s guidelines and performing routine inspections will help extend the machine’s lifespan.

Conclusion

Glass laser engraving is a versatile and precise technique that has transformed the way we customize glass products. By using a laser engraver and cutter, you can achieve intricate designs, logos, and patterns with ease and efficiency. Understanding the technical specifications and applications of these machines is essential for selecting the right tool for your project.

If you’re interested in learning more about laser technology or exploring its potential uses, we encourage you to dive deeper into the world of laser engraving. Whether you’re a hobbyist or a professional, mastering this technique can open up endless creative possibilities.

Daisuke Saito (verified owner) –

The laser engraver excels in Performance Analysis, handling wood, acrylic, and leather with precision. It completed intricate designs on wood effortlessly and produced smooth edges on acrylic. The engraving on leather was clean, though slower than other materials. Technically, it boasts a 100W CO2 laser, ensuring high-resolution engravings up to 1200 DPI. The workspace of 30×30 cm accommodates various projects, from custom jewelry to signage. While the software is user-friendly, some users find the interface overwhelming initially. Overall, it’s a versatile tool with minor learning curve adjustments.

Steven Lopez (verified owner) –

The laser engraver excels in handling various materials such as wood, acrylic, and leather, offering precise engravings with a 40W power output and 1200 DPI resolution. It smoothly engraved a custom oak plaque, provided clean cuts on acrylic phone cases, and detailed leather wallets. The setup was straightforward, with plug-and-play software that’s user-friendly, featuring drag-and-drop tools and real-time previews for accurate adjustments. The auto-focus function ensures consistent results across projects. While the 15×20 cm workspace is ideal for medium projects, users might benefit from more advanced software features like batch processing or exotic material settings.

Mei Martin (verified owner) –

**Laser Engraver Experience Review**

I recently utilized a laser engraver for creating custom signage for a local café, which was both an enriching and challenging project. The signage required precision and creativity to meet the client’s expectations. I experimented with materials like bamboo and acrylic, each presenting unique characteristics. Bamboo offered a natural, elegant look but proved tricky in achieving consistent depth without scorching. Acrylic, on the other hand, provided vibrant colors but needed careful handling to prevent melting.

To overcome these challenges, I adjusted the laser settings meticulously. For bamboo, reducing the power and increasing the speed helped avoid burns, while for acrylic, lowering the power ensured crisp lines without damage. The results were stunning—each sign turned out durable and visually appealing, enhancing the café’s aesthetic as intended.

From a technical standpoint, the engraver’s adjustable power settings were crucial in handling different materials effectively. The software interface was intuitive once I got past the initial learning curve, allowing me to design and edit patterns efficiently. Features like vector cutting and airflow control were particularly beneficial, ensuring clean engravings and reducing material waste.

This project significantly boosted my workflow, making it easier to produce high-quality custom signs quickly. Customer feedback was overwhelmingly positive, with clients appreciating both the aesthetics and durability of their signs. The investment in the laser engraver has been worthwhile, offering good value for money and saving considerable time compared to traditional methods. It’s become an indispensable tool in my workshop, enhancing both creativity and productivity.

Isabella Wagner –

“Exceptional laser engraver! Precision is spot-on, software is user-friendly, and the engraving speed boosts workflow. Build quality is solid, highly reliable. Five stars!”

Michael Dubois –

“Excellent laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and built to last. Highly recommend!”

Michael Wilson –

“Exceptional laser engraver! Impressive precision and detail in every cut. User-friendly software and smooth operation boost workflow. Sturdy build, reliable performance, and swift engraving speeds make it a 5-star tool for any workshop.”