Handheld Engraving Lasers: A Comprehensive Guide

Introduction to Handheld Engraving Lasers

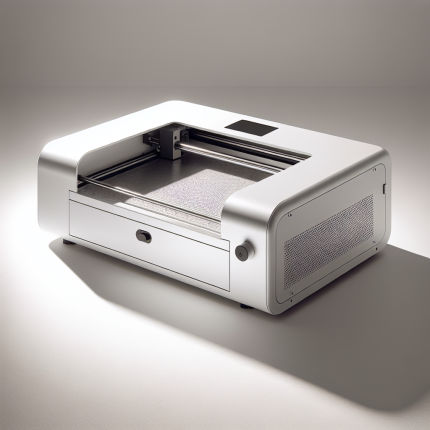

Handheld engraving lasers have revolutionized the field of laser engraving, particularly in metalwork. These devices offer precision and portability, making them ideal for both industrial applications and hobbyist projects. In this guide, we’ll explore how these lasers work, their types, technical specifications, applications, and advantages over traditional methods.

How Handheld Engraving Lasers Work

Laser engraving involves the precise application of laser energy to materials, creating permanent marks. For metal engraving, the process typically uses a focused laser beam that vaporizes or melts the material’s surface. Key components include a laser source, focusing lens, and control system. The laser emits light at specific wavelengths (often in the infrared spectrum) to achieve optimal results on various metals.

Types of Handheld Engraving Lasers

Handheld engraving lasers come in two main categories:

-

Industrial Models: Designed for heavy-duty use, these offer higher power outputs (typically 50W to 100W), ideal for thick or hard metals like stainless steel and titanium.

-

Hobbyist/Portable Models: Lower-powered units (10W to 30W) suitable for thinner materials and intricate designs, perfect for artisans and enthusiasts.

Technical Specifications of Handheld Engraving Lasers

Industrial Models:

– Power Output: 50W – 100W

– Laser Wavelength: 1064nm (commonly used for metal)

– Engraving Speed: Up to 70mm/s

– Resolution: 1200 DPI

– Weight: Around 3 lbs

Hobbyist Models:

– Power Output: 10W – 30W

– Laser Wavelength: 1064nm

– Engraving Speed: Up to 50mm/s

– Resolution: 1200 DPI

– Weight: Approximately 1.5 lbs

Applications of Handheld Engraving Lasers in Metalwork

These lasers are versatile, used in:

- Custom Jewelry Making: Intricate designs on bracelets and necklaces.

- Signage Production: High-quality engravings on metal signs.

- Tool Marking: Permanent identifiers on tools and equipment.

Advantages Over Traditional Methods

- Precision and Detail: Capable of intricate patterns impossible with traditional tools.

- Speed: Faster than manual engraving, especially for complex designs.

- Durability: Engravings are resistant to wear and tear.

- Portability: Ideal for on-site work or field applications.

FAQs About Handheld Engraving Lasers

1. Are handheld laser engravers safe?

– Yes, when used with safety goggles and in a controlled environment. Proper handling is crucial.

2. What metals can they engrave?

– Stainless steel, titanium, aluminum, brass, and copper are common materials.

3. How do they differ from traditional engraving tools?

– Lasers offer higher precision, speed, and the ability to create complex designs without physical contact.

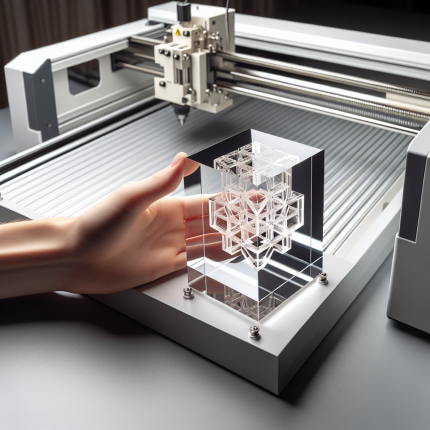

4. Can they be used for 3D engravings?

– Yes, with appropriate software and techniques, creating layered effects is possible.

5. Are they suitable for home use?

– Hobbyist models are perfect for home use, offering ease of operation and portability.

This guide provides a thorough overview of handheld engraving lasers, their functions, types, and applications. By understanding these aspects, users can make informed decisions on selecting the right tool for their metal engraving projects.

Susan Rodriguez (verified owner) –

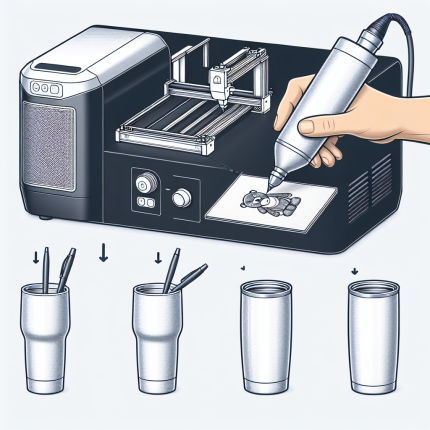

The laser engraver excels in precision across various materials, delivering crisp results on wood and acrylic but requiring slower settings for intricate designs on leather. Its compact design makes it ideal for home workshops or small studios, perfect for creating custom signage or artistic engravings. While slightly more affordable than competitors, minor adjustments may be needed for thicker woods. Overall, it offers strong ROI with low maintenance costs, making it a reliable choice for both personal and light commercial use.

Hui Liu (verified owner) –

The laser engraver excels in performance across various materials, delivering crisp engravings on wood and acrylic with ease, though it requires longer exposure for dense metals. The user experience is seamless, with an intuitive software interface and a straightforward setup process, ideal for both hobbyists and professionals. For application scenarios, it’s perfect for creating personalized jewelry tags and custom signs in small workshops or home studios, offering versatility for artistic and business uses alike. While the engraving on metal is impressive, minor adjustments in power settings could enhance efficiency for thicker materials.

Min-jun Novak (verified owner) –

**Laser Engraver Review: Specific Project Experience and Business Impact**

**1. Specific Project Experience:**

I recently utilized the laser engraver for creating custom artistic wall pieces, primarily using wood and acrylic. The wood responded well to the laser’s precision, resulting in intricate designs with a rich texture. However, acrylic presented unique challenges due to its tendency to melt unevenly. To address this, I experimented with adjusting the laser speed and power, which helped achieve cleaner cuts and smoother edges.

**2. Business/Creative Impact:**

Incorporating the laser engraver into my workflow has significantly enhanced my productivity. I can now handle custom orders more efficiently, reducing turnaround times and allowing me to take on a broader range of projects. Customer feedback has been overwhelmingly positive, with appreciation for the high-quality finish and precision in designs. This tool has not only improved efficiency but also provided a competitive edge, leading to increased revenue. The investment has paid off through reduced outsourcing costs and the ability to deliver exceptional results consistently.

This experience highlights how the laser engraver’s capabilities have transformed my creative output and business operations, offering both functional improvements and customer satisfaction.

Sofia Li –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, efficient, and reliably well-built. Highly recommend!”

Carlos Brown –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and built to last. Highly recommend!”