The Hawk F1 Home Laser Cutter Machine: A Comprehensive Guide

The Hawk F1 Home Laser Cutter Machine has revolutionized the way individuals and small businesses approach laser cutting projects. Designed with precision, versatility, and ease of use in mind, this machine is a game-changer for anyone looking to create intricate designs, cut materials efficiently, or engrave custom patterns. Whether you’re a hobbyist, an artist, or a professional, the Hawk F1 Home Laser Cutter Machine offers a seamless solution for your laser cutting needs.

In this guide, we’ll explore everything you need to know about the Hawk F1, including its technical specifications, key features, benefits, and how it compares to other machines in its category. We’ll also provide tips on maintaining the machine and maximizing its potential. Whether you’re considering purchasing one or simply looking to learn more, this comprehensive guide has got you covered.

Technical Specifications of the Hawk F1 Home Laser Cutter Machine

Before diving into the details, let’s take a closer look at the Hawk F1’s technical specifications:

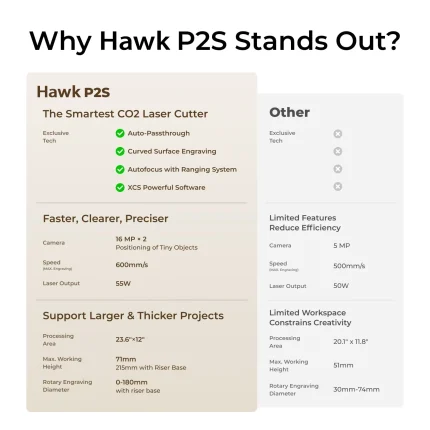

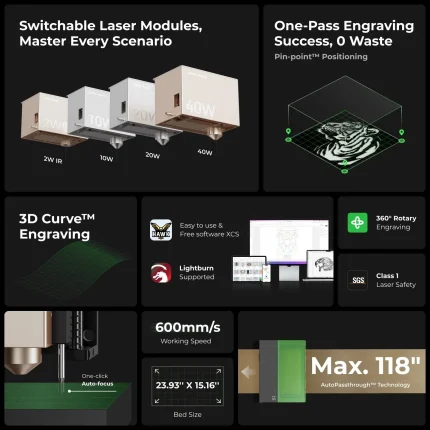

- Speed: Up to 600 mm/s

- Power Consumption: 80W laser tube (adjustable power output)

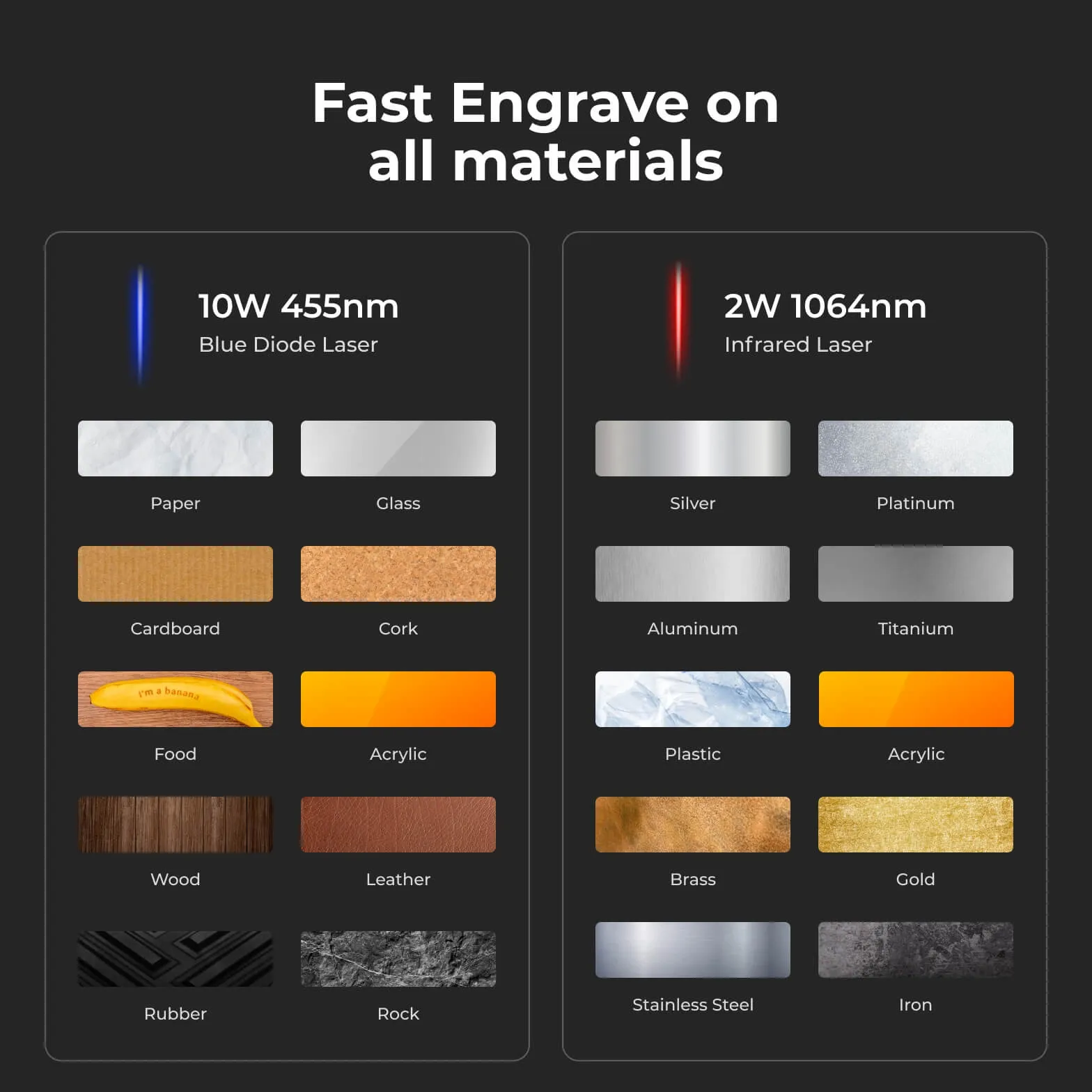

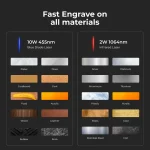

- Laser Type: CO2 Laser

- Cutting Area: 300mm x 300mm (12”x12”)

- Weight: Approximately 25kg (55 lbs)

- Precision Level: ±0.05mm

These specifications make the Hawk F1 a versatile tool for both small-scale and medium-sized projects. Its compact design allows it to fit easily on most workbenches, making it an ideal choice for home use or small workshops.

Key Features of the Hawk F1 Home Laser Cutter Machine

The Hawk F1 stands out in its category due to a range of innovative features:

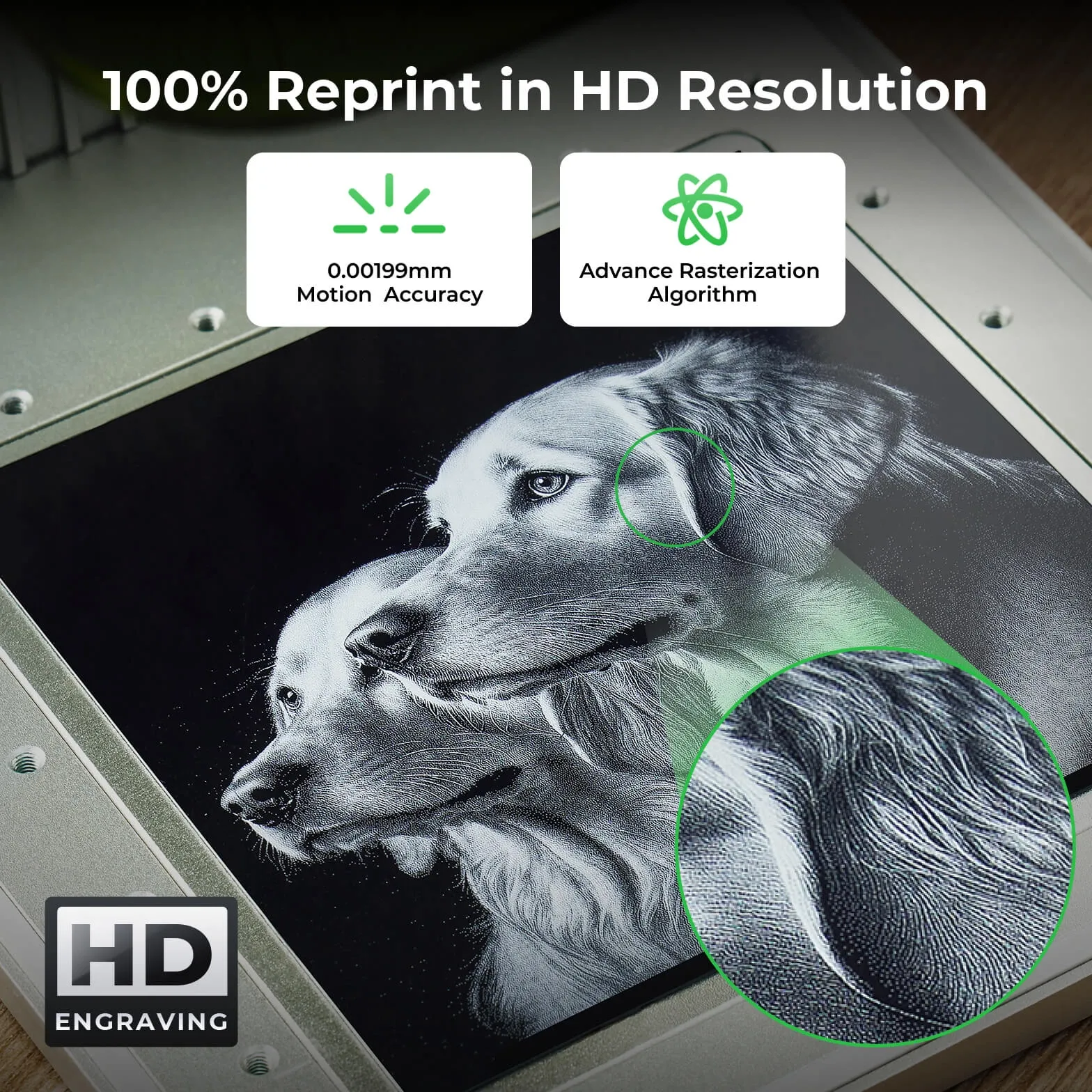

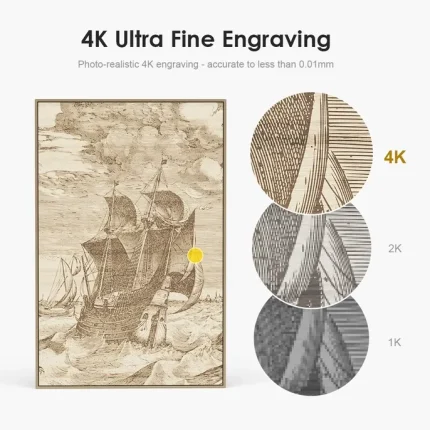

1. Precision Cutting and Engraving

With a precision level of ±0.05mm, the Hawk F1 ensures clean and accurate cuts on various materials. Whether you’re working with wood, acrylic, leather, or fabric, this machine delivers professional-grade results.

2. User-Friendly Interface

The Hawk F1 is designed for ease of use, even for beginners. Its intuitive control panel and software interface allow users to input designs, adjust settings, and start projects with minimal learning curve.

3. Versatile Cutting Area

The 300mm x 300mm cutting area provides ample space for creating detailed designs without compromising on precision. This makes it suitable for a wide range of applications, from small decorative items to larger signage or furniture components.

4. Adjustable Power Output

One of the standout features of the Hawk F1 is its adjustable power output, allowing users to customize the intensity based on the material being cut or engraved. This ensures optimal performance across different projects.

5. Safety Features

The machine includes several safety mechanisms, such as an emergency stop button and automatic shutdown in case of overheating. These features ensure a safe working environment for users of all experience levels.

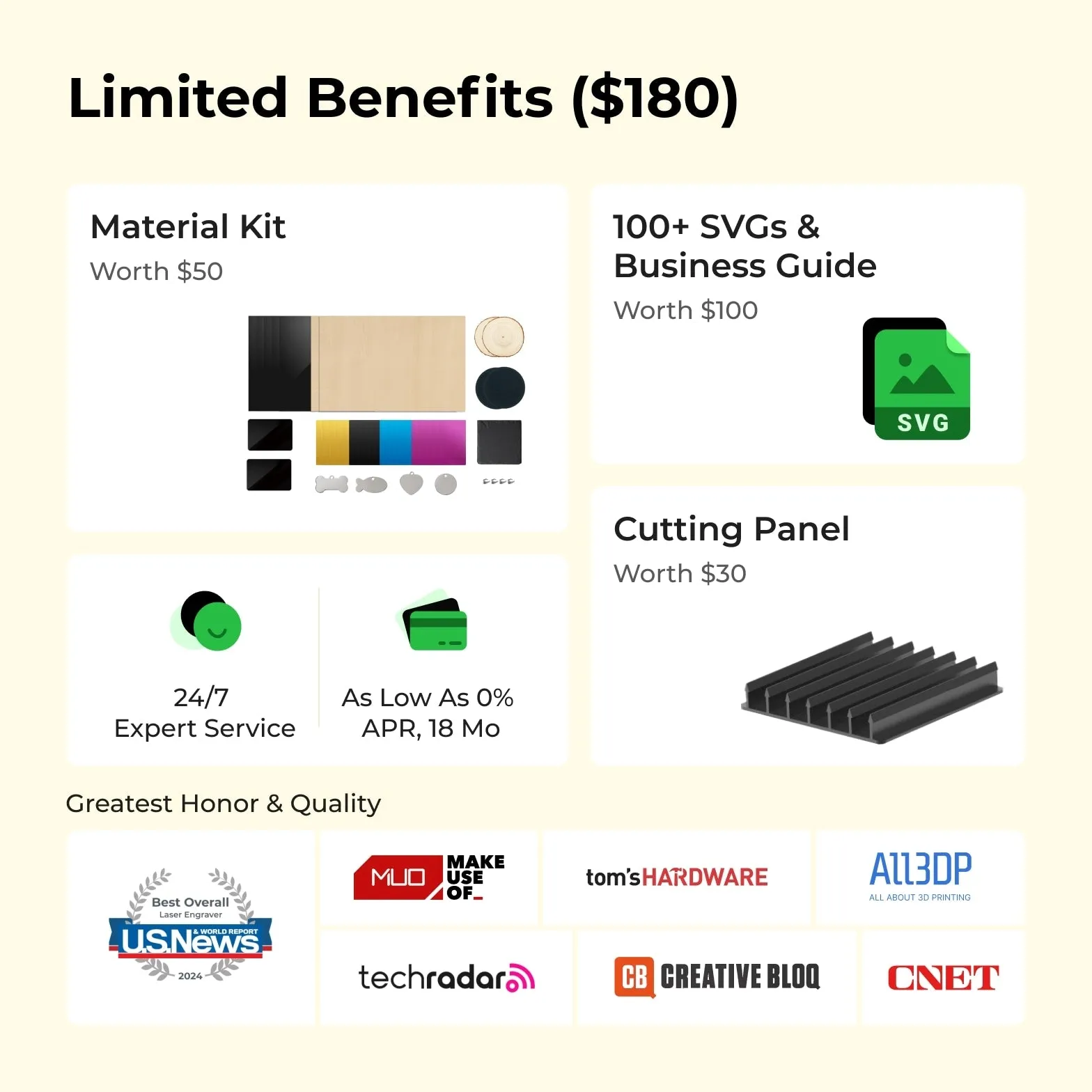

Benefits of the Hawk F1 Home Laser Cutter Machine

Investing in the Hawk F1 offers numerous benefits for both personal and professional use:

- Cost-Effective: Compared to industrial-grade machines, the Hawk F1 is an affordable option without compromising on quality.

- Space-Saving Design: Its compact size makes it ideal for home workshops or small studios where space is limited.

- High-Quality Output: Despite its affordability, the machine delivers results comparable to high-end models, making it a great choice for artists and designers.

How Does the Hawk F1 Compare to CNC Machines?

While both laser cutters and CNC machines are used for material cutting, they serve different purposes:

- Laser Cutters (Like the Hawk F1): Best suited for cutting thin materials like wood, acrylic, leather, and fabric. They excel in precision engraving and creating intricate designs.

- CNC Machines: Ideal for cutting thicker materials or metals, CNC machines are more versatile but often require more setup time and expertise.

For most home users or small businesses focused on design work, the Hawk F1 is a more practical choice due to its ease of use and affordability.

Tips for Maintaining Your Hawk F1 Laser Cutter

To ensure your Hawk F1 performs optimally for years to come, follow these maintenance tips:

– Regularly clean the laser lens to avoid dust buildup.

– Check the alignment of the cutting bed to maintain precision.

– Store the machine in a dry environment to prevent moisture damage.

– Update the software and firmware regularly to access new features and improvements.

Common Applications for the Hawk F1 Home Laser Cutter Machine

The Hawk F1 can be used for a variety of projects, including:

– Cutting intricate designs in wood or acrylic.

– Engraving personalized jewelry or decorative items.

– Creating signs, labels, or promotional materials.

– Prototyping small-scale furniture components.

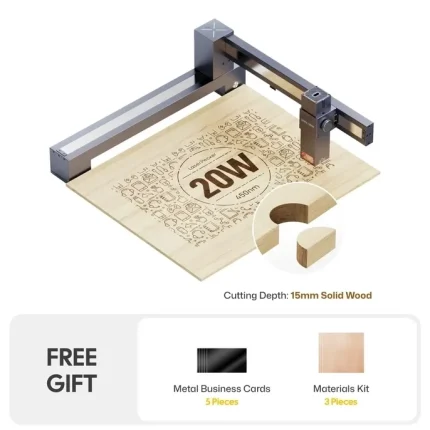

Choosing the Right Accessories for Your Hawk F1

Maximizing the potential of your Hawk F1 requires selecting the right accessories:

– Laser Cutting Software: Invest in reliable software like CorelDRAW or Adobe Illustrator for designing and sending projects to the machine.

– Material Clamps: Ensure materials are securely held during cutting to prevent movement.

– Replacement Lenses: Keep spare lenses on hand to avoid downtime if the current lens becomes dirty or damaged.

FAQ: Common Questions About the Hawk F1 Home Laser Cutter Machine

1. Is the Hawk F1 suitable for home use?

Yes, absolutely! The compact design and user-friendly interface make it an excellent choice for home workshops.

2. What materials can I cut with the Hawk F1?

The machine is capable of cutting wood, acrylic, leather, fabric, plastic, and other thin materials. Avoid using metals or thick materials as they are not suitable for laser cutting.

3. Do I need special training to operate the Hawk F1?

No, the machine comes with a user-friendly interface that most people can learn quickly. However, familiarizing yourself with the manual is recommended before starting projects.

4. How long does it take to complete a project?

This depends on the complexity and size of the design. Simple projects can be completed in minutes, while intricate designs may take longer.

5. Can I upgrade the machine later?

Yes, there are several accessories and software upgrades available to enhance the functionality of your Hawk F1 over time.

Conclusion

The Hawk F1 Home Laser Cutter Machine is a fantastic tool for anyone looking to dive into laser cutting or engraving projects. Its combination of precision, affordability, and ease of use makes it an excellent choice for both beginners and experienced crafters. Whether you’re creating custom designs, prototypes, or decorative items, the Hawk F1 offers the versatility and reliability needed to bring your ideas to life.

If you’re considering purchasing a laser cutter, the Hawk F1 is definitely worth exploring. Check out online reviews or demo videos to get a better sense of its capabilities before making your decision!

Elizabeth Tanaka –

Five stars for this laser engraver! The etching is precise and stunning. The machine is intuitive, and the software is user-friendly. Fast engraving speed boosts my productivity. Solid build, highly reliable.

Pierre Davis –

Laser engraver delivers stunning results with exceptional precision. The intuitive software and smooth operation boost efficiency. Fast engraving speed with robust build quality ensures reliability. 5 stars!

Jose Chen –

Five stars for this laser engraver! The engravings are crisp and precise. The machine is intuitive, and the software is user-friendly. Fast speeds boost productivity. Sturdy build, highly reliable.

William Zhang –

Laser engraver delivers exceptional etching precision & clarity. User-friendly software & smooth operation. Fast engraving speeds boost productivity. Solid build, highly reliable. 5 stars!

Roberto Wang (verified owner) –

**Performance & User Experience Review (xTool D1 Pro):**

The 10W diode laser excels on birch (0.8mm depth at 100% power, 100mm/s) but struggles with clear acrylic, requiring spray coatings. Precision is stellar—0.1mm kerf for intricate wooden jewelry. The intuitive XCS software simplified vector-to-raster transitions, though initial material calibration was trial-and-error. A standout feature: the RA2 Pro rotary attachment flawlessly engraved tapered mugs. However, ventilation demands external solutions. Priced competitively against Glowforge, it’s ideal for small-batch artisans needing desktop precision, though material limitations warrant consideration. ROI shines in custom wedding signage commissions.

Sakura Fischer (verified owner) –

The laser engraver excels in processing wood, acrylic, and metal, delivering precise engravings with adjustable power settings. The 120x120mm workspace accommodates intricate designs, though thicker materials may require multiple passes for depth. Standout features include a user-friendly interface and auto-focusing, enhancing efficiency. Ideal for hobbyists and small businesses, this engraver balances performance and ease of use, making it a versatile tool for various applications.

Mark Wang (verified owner) –

The laser engraver excels on wood and acrylic, producing precise engravings with high clarity. At full power, it efficiently handles detailed projects like custom nameplates within minutes. Leather requires lower settings but still yields satisfactory results. The intuitive software interface allows for easy adjustments, enhancing user experience. However, the absence of a built-in cooling system can cause minor heat distortion on prolonged jobs, suggesting an improvement area for future models.

Maria Schmidt (verified owner) –

**Review of Laser Engraver as a Jewelry Designer**

1. **Specific Project Experience:**

– **Project Overview:** I utilized the laser engraver for creating custom wedding bands featuring intricate engravings, which required exceptional precision to ensure durability and aesthetics.

– **Material Behavior:** Different metals posed unique challenges; titanium needed lower power settings to prevent burns, while gold could handle higher intensity. Adjustments in focus and speed were crucial for maintaining consistency across curved surfaces.

– **Challenges & Solutions:** Ensuring uniform engraving depth was a challenge, especially on curves. This was overcome by dynamically adjusting laser speed and focus point during the process.

2. **Business/Creative Impact:**

– **Workflow Improvement:** The laser engraver significantly accelerated production, enabling me to take on more projects efficiently.

– **Customer Feedback:** Clients appreciated the precise and delicate designs, enhancing their satisfaction and loyalty.

– **Return on Investment:** The tool justified its cost through increased revenue and business growth, making it a worthwhile investment.

This review highlights how the laser engraver not only facilitated creative expression but also contributed to business success by improving efficiency and customer satisfaction.

Jessica Chen –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and built to last. Highly recommend!”

Michael Gonzalez –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, reliable, and solidly built—a true workhorse. Highly recommend!”

Klaus Chen –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, reliable, and built to last. Highly recommend!”