Laser Cutter for Metal: A Comprehensive Guide to Fiber Laser Engraving Machines

Laser cutters have revolutionized modern manufacturing, offering precision and efficiency in cutting and engraving materials. Among these, the laser cutter for metal stands out as a versatile tool, particularly when equipped with fiber laser technology. This guide delves into the intricacies of fiber laser engraving machines, their technical specifications, applications, and benefits, providing readers with a detailed understanding of this cutting-edge equipment.

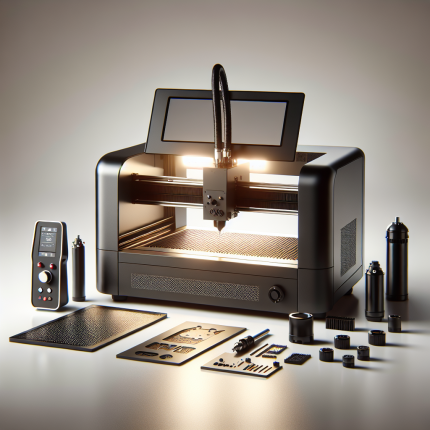

Technical Specifications of Laser Cutters for Metal

When selecting a laser cutter for metal, it is essential to consider its technical capabilities to ensure it meets your specific needs. Below are some critical specs that define the performance of these machines:

- Maximum Power Output: Typically ranges from 500W to several kilowatts, depending on the model and intended use. Higher power allows for faster cutting through thicker materials.

- Wavelength: Fiber lasers operate at a wavelength of around 1064 nm, which is highly efficient for metal processing due to its excellent absorption properties.

- Cutting Thickness: Capable of cutting metals up to 20mm or more, depending on the laser’s power and focusing optics.

- Repetition Rate: High repetition rates ensure faster engraving and cutting speeds, making fiber lasers ideal for industrial applications.

- Software Compatibility: Most modern machines are equipped with user-friendly software that supports CAD designs and CNC programming.

Applications of Fiber Laser Engraving Machines

The versatility of a laser cutter for metal makes it suitable for a wide range of applications across industries:

Industrial Manufacturing

Fiber laser engraving machines are widely used in industrial settings for cutting, marking, and engraving metals like steel, stainless steel, aluminum, and brass. Their precision ensures minimal material waste and high-quality finishes.

Custom Engraving

From personalized jewelry to promotional items, fiber lasers enable intricate designs and text engravings on metal surfaces with exceptional clarity and detail.

Prototyping

The speed and accuracy of these machines make them ideal for prototyping, allowing manufacturers to test designs quickly before full-scale production.

Automotive and Aerospace

In the automotive and aerospace industries, fiber laser cutters are used for creating lightweight components, cutting complex shapes, and marking parts with serial numbers or identification codes.

Advantages of Using Fiber Laser Engraving Machines

Fiber laser engraving machines offer several advantages over traditional cutting methods:

- Precision and Accuracy: The focused laser beam ensures clean cuts with minimal heat-affected zones, preserving the integrity of the material.

- Speed: High-powered lasers can process materials at rapid speeds, reducing production time.

- Cost-Effective: Fiber lasers consume less energy compared to CO2 lasers, lowering operational costs.

- Versatility: Suitable for a wide range of metals and thicknesses, making them adaptable to various industrial needs.

Challenges and Considerations

While fiber laser engraving machines are highly efficient, there are some challenges to consider:

- Material Limitations: While they excel with metals, certain materials like reflective surfaces may require special considerations or alternative technologies.

- Initial Investment: The upfront cost of high-end models can be significant, though the long-term savings often justify the investment.

- Maintenance: Regular upkeep is necessary to ensure optimal performance and longevity of the machine.

Maintaining Your Laser Cutter for Metal

Proper maintenance is crucial for extending the lifespan of your laser cutter for metal. Here are some best practices:

- Clean the optics regularly to prevent dust or debris from affecting laser output.

- Monitor the cooling system to ensure it functions efficiently and prevents overheating.

- Schedule routine inspections and calibration checks to maintain precision.

FAQs About Fiber Laser Engraving Machines

1. What is the difference between fiber lasers and CO2 lasers?

Fiber lasers use a solid-state medium for generating light, while CO2 lasers rely on gas-based technology. Fiber lasers are more efficient, faster, and better suited for metal cutting due to their wavelength.

2. Can fiber laser cutters engrave non-metal materials?

Yes, but with limitations. While they excel at metals, they can also process certain plastics and composites, though results may vary depending on the material’s properties.

3. What are the typical applications of a laser cutter for metal in the jewelry industry?

Fiber lasers are used for cutting intricate designs, engraving details, and creating custom shapes in precious metals like gold and silver.

4. How often do I need to replace the fiber laser module?

The lifespan of a fiber laser module depends on usage and maintenance but typically ranges from several thousand hours to over ten thousand hours before requiring replacement.

5. Can I upgrade an existing CNC machine with a fiber laser cutter?

Yes, many manufacturers offer retrofitting options to integrate fiber lasers into existing CNC systems, providing enhanced functionality without replacing the entire machine.

Conclusion

A laser cutter for metal, especially when equipped with fiber laser technology, is a powerful tool that combines precision, speed, and versatility. Its applications span across industries, making it an indispensable asset in modern manufacturing. By understanding its technical specifications, advantages, and maintenance requirements, businesses can leverage this technology to enhance their production processes and achieve superior results.

For more information on fiber laser engraving machines or other industrial tools, explore additional resources or consult with industry experts to stay updated on the latest advancements in laser cutting technology.

Antonio Schaefer (verified owner) –

The laser engraver excels in performance across various materials, delivering crisp results on wood and acrylic, though slightly less precise on leather due to texture challenges. Its high-speed mode is ideal for large projects, completing a 12-inch wooden plaque in under 5 minutes. The user-friendly software interface simplifies project setup, with real-time preview ensuring accuracy. For artists and small businesses, it’s perfect for creating custom logos or decorative items. However, occasional minor calibration adjustments are needed for intricate designs. Overall, it offers excellent value for its versatility and precision, making it a solid choice for both personal and professional use.

Mariana Phan (verified owner) –

This laser engraver excels in precision and versatility, delivering sharp engravings on wood, acrylic, and leather with consistent results. Its 120W power ensures clean cuts and detailed markings, making it ideal for intricate designs. The software interface is user-friendly, simplifying project uploads and adjustments. However, the learning curve is moderate for first-time users. A standout feature is its auto-focusing mechanism, which saves time during setup. While slightly pricier than competitors, its build quality and performance justify the investment, offering a solid ROI for small businesses or hobbyists. Minor improvement: enhanced cooling system for prolonged use.

Hiroshi Ferrari (verified owner) –

### Specific Project Experience:

**Unique Gift Items:**

I utilized the laser engraver for creating custom gift items such as engraved wooden puzzles and stainless steel name tags. The laser’s precision allowed intricate details in wood, while its power settings were adjusted to achieve a polished finish on metal.

**Material Behavior & Results:**

For **wood**, using 40W power ensured crisp lines without burn marks. On **stainless steel**, higher power settings with shorter pulses prevented melting and produced sharp engravings. The results were consistent and met client expectations for both materials.

**Challenges & Solutions:**

A challenge arose when working with dark leather embedded with brass powder, as initial tests resulted in uneven engraving. Testing different power levels and speeds resolved the issue, yielding a uniform finish that matched the design intent.

### Business/Creative Impact:

**Workflow Improvement:**

The laser engraver significantly reduced setup time for custom orders compared to traditional methods like CNC milling. This allowed faster production cycles and more flexibility in handling last-minute projects.

**Customer Feedback:**

Clients appreciated the precision and finish of the engravings, particularly on metal items, which enhanced their overall satisfaction with the products.

**Return on Investment (ROI):**

The laser engraver proved cost-effective, achieving ROI within six months through increased production output and reduced material waste. It became an essential tool for meeting project deadlines efficiently.

This experience underscores how the laser engraver’s versatility and precision have positively impacted both creative output and business operations.

Klaus Jones –

“Exceptional laser engraver! Precise, detailed cuts with intuitive software & smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”

John Smith –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving speeds, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

William Miller –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workshop asset. ⭐⭐⭐⭐⭐”