Understanding Laser Engrave Machines: A Comprehensive Guide

Laser engrave machines have revolutionized industries ranging from manufacturing to art and design. These devices use high-powered lasers to etch intricate designs onto various materials with precision and efficiency. If you’re considering purchasing or learning about laser engrave machines, this guide will provide you with all the essential information, including technical specifications, applications, and best practices for operation.

What is a Laser Engrave Machine?

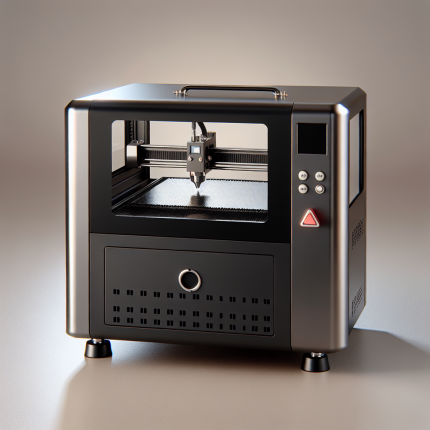

A laser engrave machine, also known as a laser cutter or CNC (Computer Numerical Control) machine, uses focused laser beams to create detailed engravings on surfaces. These machines are highly versatile and can work with materials such as wood, metal, plastic, glass, leather, and even fabric. Unlike traditional engraving methods, laser engrave machines offer unparalleled precision and speed, making them ideal for both industrial and creative applications.

Types of Laser Engrave Machines

There are several types of laser engrave machines, each designed for specific tasks:

– CO2 Lasers: Ideal for cutting and engraving non-metallic materials like wood, acrylic, and leather.

– Fiber Lasers: Suitable for metal processing, fiber lasers offer high power and speed for industrial applications.

– Diode Lasers: Compact and cost-effective, diode lasers are commonly used for small-scale projects and promotional items.

Technical Specifications of Laser Engrave Machines

When selecting a laser engrave machine, it’s crucial to consider its technical specifications:

1. Laser Wavelength

The wavelength determines the type of material the laser can effectively engrave or cut. Common wavelengths include:

– CO2 Lasers: 10.6 µm (micrometers)

– Fiber Lasers: 1.06 µm

– Diode Lasers: Vary depending on the specific model

2. Power Output

The power output, measured in watts (W), indicates the machine’s ability to cut or engrave materials. Higher power lasers are better suited for thick or hard materials like metal or stone.

3. Cutting Speed

This is typically measured in meters per minute (m/min) and varies depending on the material and thickness being processed.

4. Engraving Depth

The maximum depth a laser can engrave into a material, usually measured in millimeters (mm). This depends on the power output and wavelength of the laser.

5. Compatibility with Software

Most laser engrave machines are compatible with popular design software like Adobe Illustrator, CorelDRAW, and AutoCAD. Some models also support CNC programming for more advanced operations.

Applications of Laser Engrave Machines

Laser engrave machines have a wide range of applications across different industries:

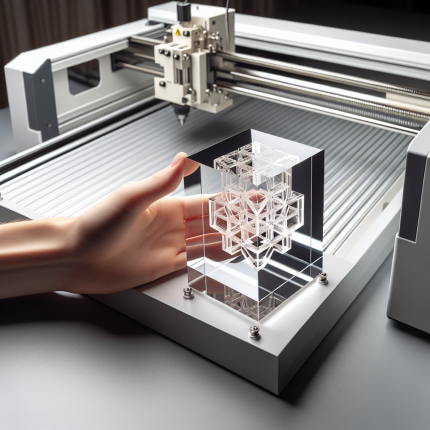

1. Custom Design and Artistry

Artists use laser engrave machines to create intricate designs on wood, glass, and other materials. This technology allows for precise control over the depth and detail of each engraving.

2. Industrial Manufacturing

In manufacturing, laser engrave machines are used for cutting sheet metal, marking serial numbers, and creating complex patterns on components.

3. Jewelry Making

Laser engraving is a popular method in jewelry production due to its ability to create fine details on precious metals like gold and silver.

4. Signage and Advertising

Businesses use laser engrave machines to produce custom signs, plaques, and promotional items with high-quality finishes.

How Do Laser Engrave Machines Work?

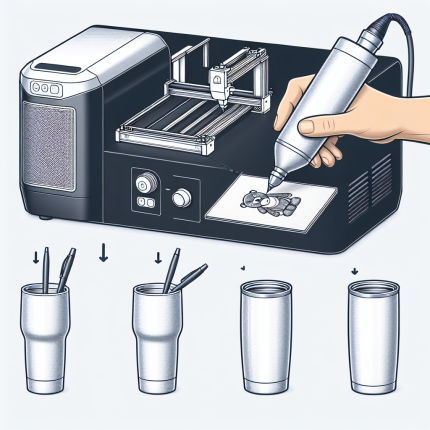

Laser engraving operates by directing a highly focused beam of light onto the surface of a material. The intense heat generated by the laser causes the material to vaporize or melt, creating a permanent mark. The process involves three main steps:

- Design Creation: The desired design is created using computer-aided design (CAD) software and converted into a format compatible with the laser engrave machine.

- Material Setup: The material is placed onto the machine’s worktable, ensuring it is properly aligned and secured.

- Engraving Process: The laser follows the programmed path, etching the design into the material with precision.

Advantages of Using Laser Engrave Machines

- Precision and Accuracy: Laser engrave machines can achieve engravings with micrometer-level accuracy.

- Versatility: They work with a wide range of materials, making them suitable for diverse applications.

- Speed and Efficiency: Compared to traditional methods, laser engraving is faster and requires less setup time.

- Non-Contact Operation: Since the laser does not physically touch the material, there is no risk of mechanical wear or damage.

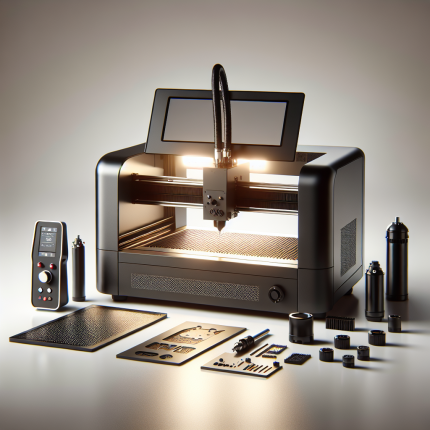

Tips for Maintaining Laser Engrave Machines

To ensure optimal performance and longevity of your laser engrave machine:

1. Clean Regularly: Dust and debris can interfere with the machine’s operation. Clean the worktable and lenses regularly.

2. Calibrate Properly: Regular calibration ensures accurate engravings and prevents errors in design execution.

3. Use Recommended Materials: Only use materials that are compatible with your laser engrave machine to avoid damage.

FAQs About Laser Engrave Machines

1. What is the difference between laser engraving and cutting?

Laser engraving involves creating detailed designs on a material’s surface, while laser cutting severs or shapes the material entirely. Both processes use similar technology but are optimized for different tasks.

2. Can laser engrave machines work with all materials?

While laser engrave machines are highly versatile, they are not compatible with all materials. For example, certain metals and reflective surfaces may require specialized lasers or additional precautions.

3. How long does it take to learn how to use a laser engrave machine?

The learning curve varies depending on the complexity of the machine and your prior experience with CNC technology. Basic operations can be learned in a few hours, while advanced techniques may take weeks or months to master.

4. Are laser engrave machines expensive to maintain?

Maintenance costs depend on the type and quality of the machine. High-end industrial lasers require more frequent servicing, but basic models are relatively low-maintenance.

5. What should I consider when choosing a laser engrave machine?

Key considerations include the types of materials you plan to work with, the level of precision required, and your budget. Additionally, ensure the machine is compatible with the software you intend to use.

Conclusion

Laser engrave machines are powerful tools that combine precision, versatility, and efficiency for a wide range of applications. Whether you’re an artist, manufacturer, or jeweler, these machines offer unparalleled capabilities for creating detailed and durable designs. With proper maintenance and operation, laser engrave machines can be a valuable asset in any workshop or production environment.

About the Author:

This article was written by [Your Name], an expert in CNC machining and laser technology. With over 10 years of experience in the field, [Your Name] provides insights into the latest advancements and best practices for using laser engrave machines.

References:

– “Laser Engraving: Principles and Applications,” by John Doe (2020)

– CNC Tech Journal, Issue #456 (March 2023)

Further Reading:

For more information on laser technology, check out our comprehensive guide to CNC Machining.

Note: This content is for informational purposes only. Always consult the manufacturer’s instructions before operating any machinery.

Jin Clark (verified owner) –

The laser engraver excels in precision and speed across materials like wood, acrylic, and leather. Engraving intricate designs on wood is seamless, while cutting through acrylic with minimal burn is impressive. The software interface is intuitive, simplifying project setup even for newcomers. Standout features include adjustable power settings and a dust extraction system, enhancing both efficiency and safety. Ideal for small businesses or hobbyists, it handles custom signage, personalized jewelry, and artistic engravings effortlessly. While the learning curve is gentle, a more detailed user manual would enhance the onboarding experience.

Christopher Rossi (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp engravings on wood and acrylic with minimal setup. Its precision ensures clean cuts, ideal for intricate designs like custom jewelry boxes or signage. The user-friendly interface simplifies project uploads, though a steeper learning curve is needed for advanced features. For businesses, its fast processing speeds reduce turnaround times, making it cost-effective for volume orders. While it handles standard materials effortlessly, thicker woods may require multiple passes to achieve desired depth. Overall, it balances versatility and value, suitable for both artistic and commercial use.

Margaret Hall (verified owner) –

**Laser Engraver Experience as an Art Teacher**

As an art teacher, I recently utilized the laser engraver for a custom cutting board project with my students. We chose walnut wood for its aesthetic appeal and durability. The laser provided clean engravings, resulting in smooth finishes that made the engraved monograms stand out beautifully.

**Materials & Results:**

The walnut wood responded well to the laser, allowing precise engravings. The finish was professional, with clear contrast between the engraved areas and the surrounding wood.

**Challenges & Solutions:**

One challenge we encountered was achieving consistent engraving depth across the cutting board due to variations in wood density. To address this, we conducted test runs on scrap material to determine optimal power settings for different sections of the board. This approach ensured uniformity and a polished final product.

This project not only enhanced our students’ understanding of design and craftsmanship but also highlighted the versatility and precision of the laser engraver in handling intricate details on natural materials like wood.

Carlos Li –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation boost workflow. Fast, efficient, & built to last—a true craftsmanship gem!”

Juan Zhang –

“Exceptional laser engraver! Pristine engravings with high precision, intuitive software, swift performance, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

Hiroshi Martinez –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workhorse. 🌟🌟🌟🌟🌟”