Laser Engraver Machines for Metal: A Comprehensive Guide

Laser engravers for metal have revolutionized the way we create intricate designs, logos, and patterns on metallic surfaces. These machines offer precision, speed, and versatility, making them indispensable in industries ranging from manufacturing to jewelry production. In this guide, we’ll explore what laser engravers for metal are, their technical specifications, applications, and more. Whether you’re a seasoned professional or new to the world of laser engraving, this article will provide valuable insights into these cutting-edge tools.

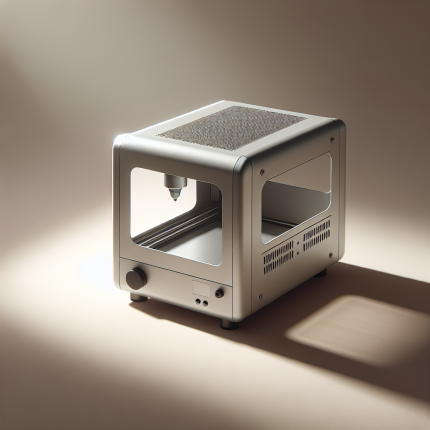

What Are Laser Engravers for Metal?

Laser engravers for metal use focused light beams to etch or mark surfaces with exceptional accuracy. Unlike traditional engraving methods that rely on mechanical cutting or stamping, laser engravers utilize high-powered lasers to remove material layer by layer. This process is ideal for creating detailed and durable markings on metals like steel, aluminum, brass, and stainless steel.

How Do Laser Engravers Work?

Laser engravers work by directing a focused laser beam at the metal surface. The intense heat generated by the laser causes the material to melt or vaporize, leaving behind a precise engraving. The machine is controlled by computer software that dictates the design, size, and depth of the engraving. This level of control ensures consistency and precision, even for complex patterns.

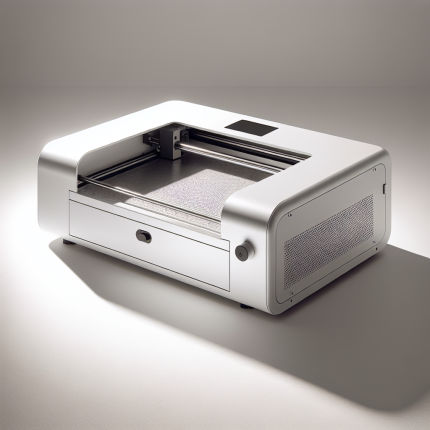

Technical Specifications of Laser Engravers for Metal

When selecting a laser engraver for metal, it’s essential to consider its technical specifications to ensure it meets your project requirements. Below are some key features to look out for:

- Laser Power Output: Measured in watts (W), the power output determines the machine’s ability to engrave or cut through different materials. Higher wattage lasers are better suited for thicker metals.

- Wavelength: The wavelength of the laser beam affects its compatibility with various materials. For metal engraving, common wavelengths include 1064 nm and 532 nm.

- Repetition Rate: This refers to how many pulses the laser can emit per second. Higher repetition rates allow for faster engraving speeds.

- Engraving Speed: Measured in inches per minute (IPM), this indicates how quickly the machine can complete a design.

- Resolution: Typically measured in dots per inch (DPI), resolution determines the level of detail achievable in engravings.

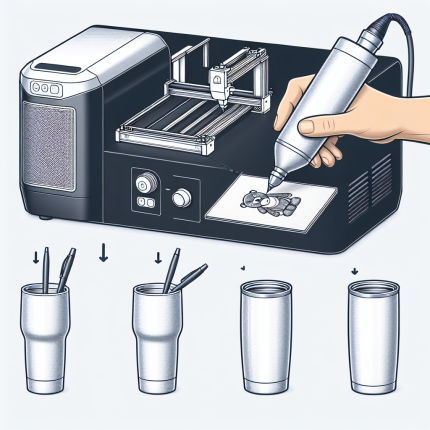

Applications of Laser Engravers for Metal

Laser engravers for metal are used in a wide range of industries due to their precision and adaptability. Some common applications include:

- Jewelry Making: Creating intricate designs, hallmarks, and logos on precious metals like gold and silver.

- Industrial Marking: Engraving serial numbers, barcodes, and other identification marks on metal components.

- Artistic Engravings: Producing custom artwork, logos, and decorative patterns on metal surfaces.

- Prototyping: Rapid prototyping of metal parts with detailed engravings for testing and design validation.

Advantages of Using Laser Engravers for Metal

Precision and Accuracy

Laser engravers for metal offer unparalleled precision, allowing for intricate designs that would be difficult or impossible to achieve with traditional methods. The laser beam’s focused intensity ensures clean cuts and sharp edges, resulting in high-quality engravings.

Speed and Efficiency

Compared to manual engraving techniques, laser engravers significantly reduce production time. Their ability to work at high speeds without compromising quality makes them ideal for large-scale manufacturing operations.

Versatility

Laser engravers can handle a variety of metals, including steel, aluminum, titanium, and precious metals like gold and platinum. They are also capable of working with different thicknesses of metal, making them versatile tools for diverse projects.

Maintenance and Care

Proper maintenance is crucial to ensure the longevity and optimal performance of your laser engraver. Regular cleaning of the machine’s optics and lenses is essential to prevent dust or debris from affecting the laser beam’s accuracy. Additionally, routine calibration of the machine will help maintain consistent engraving quality over time.

Choosing the Right Laser Engraver for Your Needs

Selecting the right laser engraver depends on several factors, including the type of metal you’ll be working with, the complexity of your designs, and the scale of your projects. It’s important to consider both the initial cost and long-term maintenance expenses when making your decision.

Conclusion

Laser engravers for metal are powerful tools that have transformed the way we create detailed and durable markings on metallic surfaces. Their precision, speed, and versatility make them indispensable in various industries, from jewelry production to industrial manufacturing. By understanding their technical specifications, applications, and maintenance requirements, you can choose the right laser engraver to meet your project needs.

FAQ Section

1. What are the advantages of using laser engravers for metal over traditional methods?

Laser engravers offer higher precision, faster processing times, and greater versatility compared to traditional engraving methods. They also reduce the risk of human error and provide consistent results.

2. Can laser engravers be used on all types of metals?

Yes, laser engravers can work with a wide range of metals, including steel, aluminum, brass, stainless steel, and precious metals like gold and platinum. However, the choice of wavelength may vary depending on the metal type.

3. How much maintenance do laser engravers require?

Regular maintenance includes cleaning the optics, calibrating the machine, and checking for wear and tear on components. Proper care ensures optimal performance and longevity of the equipment.

4. What are some common applications of laser engravers in the jewelry industry?

Laser engravers are widely used in the jewelry industry to create intricate designs, hallmarks, and custom engravings on precious metals like gold, silver, and platinum.

5. Is it possible to engraved complex patterns with a laser engraver for metal?

Yes, laser engravers are capable of creating highly detailed and complex patterns with exceptional precision. Modern machines come equipped with advanced software that allows for the creation of intricate designs.

By understanding these key aspects of laser engravers for metal, you can make informed decisions about their use in your projects or business.

Jessica Carter (verified owner) –

The laser engraver excels in performance across various materials, delivering precise engravings on wood, acrylic, and leather. It handles intricate designs with ease, as seen in custom jewelry boxes and signage projects. The setup is straightforward, though familiarizing oneself with the software interface requires some time. Standout features like the focus assist tool enhance accuracy, making it a reliable choice for both hobbyists and professionals. While the learning curve is gentle, additional tutorials could aid in optimizing settings for different materials, improving efficiency further.

Sarah Dang (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp engravings on wood, acrylic, and leather. Its precision is remarkable for intricate designs, though speed slightly slows on dense textures. The user-friendly software simplifies setup, with intuitive controls that even novices can master quickly. Standout features include real-time preview adjustments and automated calibration. While it competes well in its price range, a larger workspace and interchangeable lenses would enhance versatility. Overall, it’s a solid choice for hobbyists and small-scale businesses seeking reliable engraving quality.

Lars Kim (verified owner) –

**Technical Performance**: The laser engraver excels with its high power output, enabling intricate details and precise control essential for industrial design. The software is user-friendly, supporting seamless vector imports and offering intuitive adjustments. Features like variable speed and airflow control prevent material burn, enhancing precision.

**Specific Project Experience**: In crafting handmade jewelry boxes from wood and leather, the laser’s performance was remarkable. Wood engravings were fine and detailed without burning, while leather showed clean lines with minimal charring. Challenges included adjusting settings for different materials—lower power for leather—and solutions like initial tests and protective covers ensured optimal results.

This tool significantly enhanced my workflow by providing consistent quality and versatility across materials, making it an invaluable asset in industrial design projects.

Klaus Rodriguez –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, reliable, and solidly built—a true 5-star workhorse!”

Yuki Weber –

“Exceptional laser engraver! Precision is spot-on, software is user-friendly, and the engraving speed boosts productivity. Well-built and highly reliable. 🌟🌟🌟🌟🌟”

Joseph Kim –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”