The Ultimate Guide to Laser Engraving Equipment: A Focus on High-Quality Laser Cutters

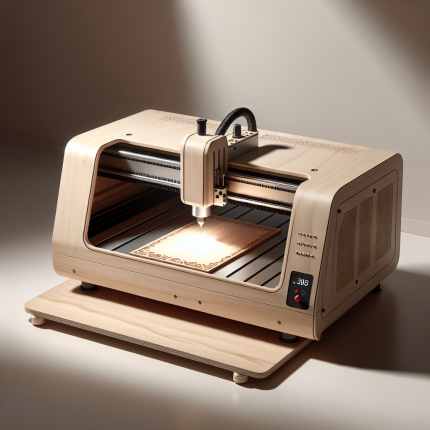

Laser engraving equipment has revolutionized industries ranging from manufacturing to artistry by offering precision, versatility, and unmatched efficiency. Among the various tools available, laser cutters stand out as indispensable for creating intricate designs and cutting through a wide range of materials. This guide delves into the technical aspects, applications, and benefits of modern laser engraving equipment, with a particular focus on high-quality laser cutters.

Understanding Laser Engraving Equipment

Laser engraving equipment utilizes focused light beams to etch or cut materials with exceptional accuracy. Unlike traditional methods, this technology allows for non-contact processing, reducing wear and tear on tools while delivering superior results. Laser cutters are a subset of this equipment, designed specifically for slicing through materials with precision.

Technical Specifications of Laser Cutters

When evaluating laser cutters, several technical specifications determine their performance and suitability for different applications:

- Wavelength: The wavelength of the laser determines its interaction with various materials. Common wavelengths include 1064 nm (Nd:YAG), 532 nm (green lasers), and 10.6 µm (CO₂ lasers).

- Power Output: Measured in watts, this indicates the intensity of the laser beam. Higher power output is typically required for thicker materials or faster cutting speeds.

- Repetition Rate: This refers to the number of pulses per second the laser can produce, impacting its ability to handle intricate designs.

- Cutting Speed: The speed at which the laser can cut through a material, usually measured in meters per minute.

- Precision and Accuracy: Measured in micrometers (µm), this determines how fine the details can be engraved or cut.

Applications of Laser Engraving Equipment

Laser engraving equipment is used across various industries due to its versatility:

Industrial Manufacturing

In manufacturing, laser cutters are employed for creating precise components from metal sheets, stainless steel, and aluminum. The non-contact nature of the process minimizes material deformation, making it ideal for high-precision parts.

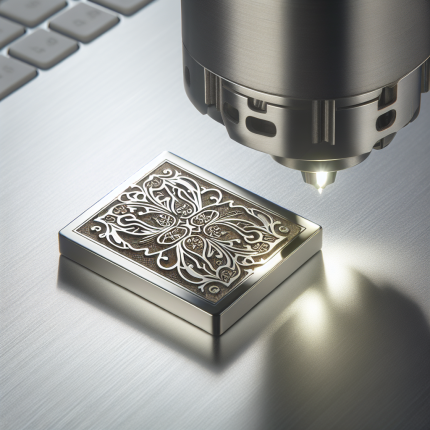

Artistic Engraving

Artists use laser engraving equipment to create detailed designs on wood, glass, and stone. This method allows for intricate patterns that would be difficult or impossible to achieve manually.

Jewelry Making

The jewelry industry benefits from the precision of laser cutters, enabling the creation of complex shapes in precious metals like gold and silver.

Prototyping

Laser engraving equipment is a favorite among product designers for rapid prototyping, as it allows quick iterations of designs without significant setup time.

Advantages of Laser Engraving Equipment

- Precision: Capable of achieving micrometer-level accuracy, laser cutters are ideal for detailed work.

- Versatility: Works with a wide range of materials, including metals, plastics, wood, and glass.

- Speed: High cutting speeds reduce production time without compromising quality.

- Cost-Effective: Minimal material waste and reduced labor costs make laser engraving equipment a cost-effective solution in the long run.

Key Considerations for Choosing Laser Engraving Equipment

When selecting laser engraving equipment, several factors should be considered:

Material Compatibility

Different materials interact with laser beams differently. For instance, metals require specific wavelengths to achieve optimal results, while plastics may require lower power settings to avoid melting.

Design Complexity

The complexity of the design will influence the choice of laser cutter. More intricate designs may require higher precision and slower cutting speeds.

Maintenance

Laser engraving equipment requires regular maintenance to ensure optimal performance. Factors such as dust collection systems and lens cleaning are critical for longevity.

Frequently Asked Questions (FAQ)

-

What is the difference between laser engraving and laser cutting?

Laser engraving involves etching designs into a material’s surface, while laser cutting slices through the material entirely. -

Can laser cutters work with all types of materials?

While laser cutters are versatile, their effectiveness depends on the material’s properties. Some materials may require specific settings or alternative methods. -

How do I ensure safe operation of laser engraving equipment?

Proper safety protocols include wearing protective eyewear, ensuring adequate ventilation, and following manufacturer guidelines for machine setup and use. -

What are the maintenance requirements for laser cutters?

Regular tasks include cleaning lenses, checking dust collection systems, and calibrating the machine to maintain precision. -

Can I switch between different materials with the same laser cutter?

Yes, but adjustments to power settings, focus, and cutting speed may be necessary depending on the material being processed.

Conclusion

Laser engraving equipment, particularly high-quality laser cutters, represents a significant advancement in manufacturing and artistic applications. Their precision, versatility, and efficiency make them indispensable tools for industries ranging from jewelry making to industrial production. By understanding their technical specifications, applications, and maintenance requirements, users can maximize the potential of this cutting-edge technology.

This guide provides a comprehensive overview of laser engraving equipment, helping you make informed decisions about its use and selection. Whether you’re an artist, manufacturer, or hobbyist, laser cutters offer unparalleled opportunities for creativity and productivity.

Satoshi Kim (verified owner) –

This laser engraver excels in precision and versatility, handling wood, acrylic, and leather with ease. For instance, intricate designs on wood showcase its high-resolution capability, while acrylic engravings demonstrate its speed without sacrificing detail. The setup was straightforward, and the intuitive software made it easy to adjust settings for different materials. A minor suggestion: adding a cooling system or improved dust extraction would enhance long-term use. Overall, it’s a reliable tool for both artistic and small-scale business applications, offering excellent value for its performance.

Marie Vu (verified owner) –

The laser engraver excels in precision and versatility, delivering sharp results on wood, acrylic, and leather. Its high power output ensures quick processing times, ideal for intricate designs or signage projects. The software interface is intuitive, though a steeper learning curve may be needed for advanced features. Compared to similar models, its improved resolution and larger workspace stand out, offering better quality and capacity. While the upfront cost is notable, the long-term savings on consumables make it a worthwhile investment for both small businesses and hobbyists seeking reliable performance.

Saki Lewis (verified owner) –

**Laser Engraver Review: Specific Project Experience & Business Impact**

As an Etsy seller, integrating the laser engraver into my workflow has transformed how I approach custom orders. Here’s my experience:

– **Unique Projects:** I’ve successfully engraved intricate designs on wood signs and personalized jewelry. The machine handles various materials seamlessly, with wood offering a beautiful burn finish and metal requiring careful adjustment of settings for precision.

– **Material Behavior & Challenges:** Wood reacts predictably, but delicate metals needed precise power control to avoid damage. By adjusting speed and power settings, I achieved clean results without compromising material integrity.

**Business/ Creative Impact:**

– **Workflow Efficiency:** The laser engraver has significantly sped up production. Detailed artwork that once took hours now takes minutes, allowing me to take on more orders without stress.

– **Customer Feedback & ROI:** Customers consistently praise the quality and personalization of my items. This tool not only attracted new customers but also increased repeat business, making the investment worthwhile in just a few months.

In summary, this laser engraver has elevated both my creative output and business efficiency, proving to be an essential asset for any Etsy seller looking to enhance their offerings.

Marco Li –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls. Fast, efficient, and built to last. Highly recommend!”

Luigi Schmidt –

“Exceptional laser engraver! Impressive precision and detail in every cut. User-friendly software and intuitive controls boost workflow. Swift engraving speeds coupled with robust build quality make it a reliable, 5-star tool.”

Wei Gonzalez –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving speeds, and robust build quality. Highly reliable and a true workhorse. 🌟🌟🌟🌟🌟”