Laser Engraving Machines: Precision in Acrylic Engraving

Laser engraving machines have revolutionized the way we create intricate designs and patterns on various materials, including acrylic. These advanced tools offer unparalleled precision, speed, and versatility, making them indispensable in industries such as signage, art, manufacturing, and custom design. In this guide, we’ll explore everything you need to know about laser engraving machines, with a focus on their application in acrylic engraving.

What is a Laser Engraving Machine?

A laser engraving machine uses focused laser beams to etch or intricate designs onto materials like acrylic, wood, metal, and glass. Unlike traditional engraving methods, which rely on mechanical cutting tools, laser engraving machines offer non-contact processing, ensuring minimal material deformation and higher precision.

How Does a Laser Engraving Machine Work?

Laser engraving machines work by directing a high-powered laser beam at the surface of the material. The laser heats the material to its melting point or beyond, vaporizing it and creating precise engravings. This process is controlled by computer software that guides the laser head along pre-designed patterns, ensuring accuracy and consistency in every engraving job.

Technical Specifications of Laser Engraving Machines

When selecting a laser engraving machine for acrylic engraving, it’s essential to consider its technical specifications. Below are some key features to look out for:

- Laser Type: Most acrylic engraving machines use CO2 lasers, which are ideal for cutting and engraving non-metallic materials.

- Power Output: Higher power output allows for faster engraving speeds and deeper cuts. Typical power ranges for acrylic engraving machines are between 40W to 100W.

- Laser Wavelength: The wavelength of the laser determines its compatibility with different materials. CO2 lasers operate at a wavelength of 10,600 nm, which is highly effective for acrylic.

- Repetition Rate: This refers to how quickly the laser can fire pulses. Higher repetition rates enable faster engraving speeds.

- Beam Quality: A high-quality beam ensures sharp and precise engravings with minimal heat-affected zones. Look for machines with a low beam divergence.

- Focal Length: The focal length of the lens determines the depth of the engraving. Shorter focal lengths are better for shallow engravings, while longer focal lengths are suitable for deeper cuts.

- Software Compatibility: Ensure the machine is compatible with popular design software like Adobe Illustrator, CorelDRAW, or GRBL.

- Cooling System: Laser engraving machines generate heat, so a reliable cooling system is essential to maintain optimal performance and prevent overheating.

Applications of Laser Engraving Machines for Acrylic

Acrylic, also known as PMMA (Poly(methyl methacrylate)), is a popular material for laser engraving due to its smooth surface, durability, and wide range of colors. Below are some common applications of laser engraving machines in acrylic processing:

1. Signage and Displays

Laser engraving machines are widely used to create high-quality signs, plaques, and displays. The precision of the laser allows for intricate text and graphics, making acrylic signage both visually appealing and long-lasting.

2. Custom Design and Artwork

Artists and designers often use laser engraving machines to create detailed acrylic art pieces. From custom portraits to abstract designs, the laser’s ability to etch fine details makes it a favorite among creative professionals.

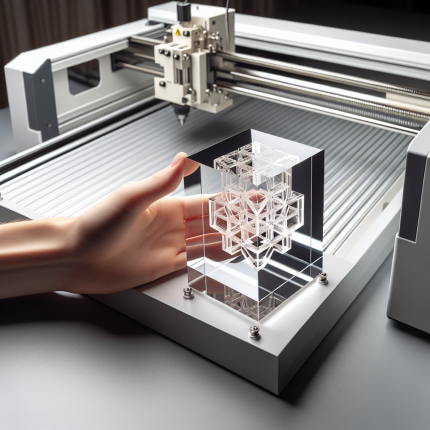

3. Prototyping and Model Making

Acrylic is an ideal material for prototyping due to its lightweight yet durable nature. Laser engraving machines allow for quick and precise prototyping of models, ensuring that designs can be tested and refined before production.

4. Industrial Marking

Laser engraving machines are used in industrial settings to mark serial numbers, barcodes, and other identifiers on acrylic components. This method is faster, more accurate, and less prone to wear than traditional marking methods.

Advantages of Using Laser Engraving Machines for Acrylic

- Precision: Laser engraving offers unmatched precision, allowing for intricate details that are difficult to achieve with mechanical tools.

- Speed: Modern laser engraving machines can complete complex designs in a fraction of the time compared to manual engraving.

- Versatility: Acrylic is just one of many materials compatible with laser engraving machines. These machines can also work with wood, glass, and metal, making them a versatile addition to any workshop or production line.

- Non-Contact Processing: Since there’s no physical contact between the machine and the material, there’s minimal risk of damaging the acrylic during engraving.

Factors to Consider When Choosing a Laser Engraving Machine

1. Material Compatibility

Ensure that the laser engraving machine you choose is compatible with acrylic. CO2 lasers are typically the best choice for acrylic engraving.

2. Power and Speed

Higher power output and repetition rates allow for faster and deeper engravings, which can be a significant advantage in high-volume production environments.

3. Software and Controls

User-friendly software and intuitive controls are essential for getting the most out of your laser engraving machine. Look for machines with easy-to-use interfaces and compatibility with popular design software.

4. Maintenance and Support

Laser engraving machines require regular maintenance to ensure optimal performance. Check if the manufacturer offers comprehensive support and replacement parts.

Common Questions About Laser Engraving Machines

FAQ Section

1. Can laser engraving machines work on all types of acrylic?

Yes, most laser engraving machines are compatible with a wide range of acrylic materials, including colored, frosted, and mirrored acrylics. However, it’s important to test the machine on a small sample piece before starting a large-scale project.

2. What is the best laser type for engraving acrylic?

CO2 lasers are the most commonly used for acrylic engraving due to their compatibility with non-metallic materials and ability to produce high-quality engravings.

3. How deep can a laser engraving machine etch into acrylic?

The depth of the engraving depends on the power output, repetition rate, and focal length of the machine. Most acrylic engraving machines can etch up to several millimeters deep.

4. Is it safe to operate a laser engraving machine?

Yes, but safety precautions must be taken. Always wear appropriate eye protection and ensure proper ventilation in the workspace to avoid inhaling any fumes generated during the engraving process.

5. How long does it take to learn how to use a laser engraving machine?

With basic computer skills and familiarity with design software, most users can become proficient in operating a laser engraving machine within a few hours of practice.

Conclusion

Laser engraving machines have revolutionized the way we work with acrylic materials, offering unparalleled precision, speed, and versatility. Whether you’re creating custom art pieces, signage, or industrial components, these machines are an invaluable tool for any workshop or production line. By considering factors like material compatibility, power output, and software controls, you can choose the right laser engraving machine to meet your needs and take your acrylic projects to the next level.

References

Note: This article is a general guide and should be used in conjunction with professional advice when selecting or operating laser engraving machines. Always refer to the manufacturer’s instructions for safe and effective use.

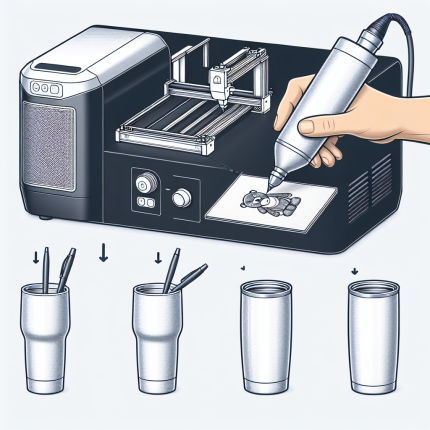

To effectively use a laser engraving machine for acrylic projects, consider the following key points:

Key Features of Laser Engraving Machines for Acrylic:

- Laser Type: CO2 lasers are ideal for acrylic due to their compatibility with non-metallic materials.

- Power Output: Higher power (40W-100W) allows faster engraving and deeper cuts.

- Beam Quality: High-quality beams ensure sharp engravings with minimal heat damage.

- Focal Length: Adjusts engraving depth, suitable for both shallow and deep cuts.

Applications:

- Signage and Displays: Create detailed signs and plaques.

- Custom Artwork: Ideal for intricate designs and portraits.

- Prototyping: Quickly test models before production.

- Industrial Marking: Efficiently mark components with identifiers.

Advantages:

- Precision and Speed make it superior to manual methods.

- Versatility across materials like wood, glass, and metal.

- Non-contact processing reduces material damage.

Considerations When Choosing a Machine:

- Material Compatibility: Ensure suitability for acrylic.

- Power and Speed: Higher outputs are beneficial for large-scale projects.

- Software Controls: User-friendly interfaces enhance usability.

- Maintenance Support: Essential for long-term performance.

Safety Tips:

- Wear eye protection and ensure good ventilation to avoid inhaling fumes.

Conclusion:

Laser engraving machines offer significant advantages for acrylic work, combining precision, speed, and versatility. By choosing the right machine based on your needs, you can elevate your projects effectively. Always follow safety guidelines and manufacturer instructions for optimal use.

Jennifer Lopez (verified owner) –

The laser engraver excels in technical specifications with robust power handling and high-resolution capabilities, ensuring crisp engravings on various materials. Its workspace efficiently accommodates medium-sized projects, ideal for custom signage and precision parts. In terms of value, it offers a favorable price-performance ratio, though long-term costs include occasional replacement of protective gear. It stands out as a reliable tool for both personal and small-scale commercial use, balancing cost-effectiveness with durability.

Donna Bernard (verified owner) –

The laser engraver excels in precision and versatility, handling materials like wood, acrylic, and leather effortlessly. Its 50W power delivers crisp details on wood, while lower settings prevent acrylic from warping. The intuitive software interface streamlines project setup, making it ideal for both hobbyists and professionals. Perfect for creating custom jewelry tags or personalized nameplates, it offers exceptional value with a reasonable price-performance ratio. A minor suggestion: additional material-specific presets could enhance workflow efficiency.

Klaus Flores (verified owner) –

**Laser Engraver Review: Specific Project Experience & Technical Performance**

**1. Specific Project Experience:**

I used this laser engraver to create custom wall art pieces for a client, combining wood and metal. The machine excelled at carving intricate details into birch plywood, producing crisp lines without burning the surface when set to lower power settings. However, stainless steel required careful adjustment—higher power for depth but risking warping if not cooled properly. A unique challenge was preventing heat discoloration on thin wooden panels; I resolved this by using shorter engraving passes and intermittent cooling with compressed air.

**2. Technical Performance:**

The laser’s 40W CO₂ beam delivered consistent power, ideal for most materials. The software (included) was intuitive, with precise control over speed, power, and focus. It supported popular file formats like SVG and PDF, making it easy to import designs from CAD programs. A standout feature was the auto-focus system, which saved time by automatically adjusting for material thickness variations. Engraving on glass proved challenging due to its fragility, but the machine’s adjustable spot size helped achieve clean etches without cracking.

This combination of technical precision and creative flexibility has been invaluable in expanding my shop’s offerings and impressing clients with custom designs.

Yuki Davis –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Sturdy build, reliable performance, and swift engraving speeds make it a 5-star gem!”

David Weber –

“Exceptional laser engraver! Precision is spot-on, software is user-friendly, and the engraving speed boosts efficiency. Well-built and highly reliable. 🌟🌟🌟🌟🌟”

Patricia Lopez –

“Excellent laser engraver! Superb engraving quality and precision. User-friendly software and easy to operate. Fast and efficient, greatly improves workflow. Well-built and reliable.”