The Ultimate Guide to Laser Engraving Metal and Wood: Equipment and Techniques

Laser engraving has become one of the most versatile and precise methods for creating intricate designs, patterns, and text on various materials. Whether you’re working with metal or wood, laser engraving offers unmatched precision and versatility. This guide explores the equipment, techniques, and considerations needed to achieve professional-quality results in both metal and wood laser engraving.

Understanding Laser Engraving: Metal vs. Wood

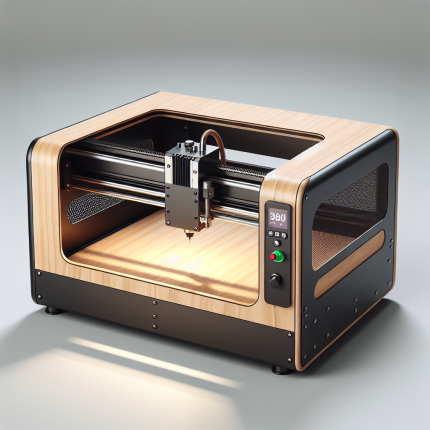

Laser engraving works by focusing a high-powered laser beam onto the surface of the material, removing or altering it to create detailed designs. The process involves three main components: the laser source, the CNC (Computer Numerical Control) machine, and the software used for design and control.

While both metal and wood can be engraved with lasers, the equipment and techniques required differ due to the unique properties of each material. Metal is harder and reflective, while wood is softer but more prone to burning or charring if not handled correctly. Understanding these differences is key to achieving optimal results.

Technical Specifications for Laser Engraving Equipment

When choosing laser engraving equipment, it’s essential to consider the type of material you’ll be working with. Below are some technical specifications that differentiate metal and wood laser engraving systems:

Metal Laser Engraving

- Laser Type: Typically uses a fiber laser or CO2 laser with a wavelength suited for metal processing (usually around 1064 nm).

- Power Output: Higher power levels (200W to 500W) are required for engraving metals like steel, stainless steel, and aluminum.

- Focus Lens: High-quality lenses designed to handle the reflective properties of metal surfaces.

- Speed Range: Slower speeds compared to wood engraving due to the higher density of metal.

Wood Laser Engraving

- Laser Type: CO2 lasers are most commonly used for wood engraving, with wavelengths around 10.6 µm.

- Power Output: Lower power levels (50W to 200W) are sufficient for engraving wood, as the material is less dense than metal.

- Focus Lens: Lenses designed for non-metallic materials to ensure precise engraving without burning the surface.

- Speed Range: Higher speeds can be used for wood, making it faster to process than metal.

Benefits of Laser Engraving Metal and Wood

Precision and Detail

Laser engraving allows for extremely detailed designs, with resolutions up to 1200 DPI or higher. This makes it ideal for creating intricate patterns, logos, or custom text.

Durability

Engravings on metal are highly durable and resistant to wear, making them suitable for industrial applications like marking tools, machinery, and jewelry. Wood engravings, while less durable than metal, can be finished with protective coatings to enhance longevity.

Versatility

Laser engraving equipment can handle a wide range of materials beyond metal and wood, including plastic, glass, and even leather. This versatility makes it a valuable tool for multiple industries.

Applications of Laser Engraving

Metal Engraving

- Custom Jewelry: Creating personalized engravings on rings, necklaces, and bracelets.

- Industrial Marking: Engraving serial numbers, part codes, and branding logos on machinery and tools.

- Artistic Expression: Sculpting detailed designs into metal sheets or sculptures.

Wood Engraving

- Furniture Customization: Adding decorative patterns or names to wooden furniture pieces.

- ** Musical Instruments**: Engraving guitar fretboards, violin scrolls, and other musical instrument parts.

- Signage and Decor: Creating custom signs, plaques, and decorative wood panels.

Maintenance and Safety Considerations

Equipment Maintenance

- Regularly clean the lens to prevent dust or debris from affecting engraving quality.

- Check the cooling system to ensure the laser remains within safe operating temperatures.

- Replace worn-out parts, such as belts or bearings, promptly to maintain machine performance.

Safety Precautions

- Always wear protective eyewear when operating a laser engraver.

- Work in a well-ventilated area to avoid inhaling fumes produced during the engraving process.

- Keep flammable materials away from the laser cutting area to prevent accidents.

Frequently Asked Questions (FAQs)

1. What is the difference between laser cutting and laser engraving?

Laser cutting involves slicing through a material entirely, while laser engraving removes only a portion of the surface to create designs or text.

2. Can I use the same laser machine for both metal and wood?

Yes, some multi-material laser engravers are designed to handle both metals and woods by adjusting settings like power and speed. However, dedicated machines for each material often yield better results.

3. How much does a laser engraving machine cost?

The cost varies depending on the type and quality of the machine. Entry-level models can range from $1000 to $5000, while industrial-grade machines may cost upwards of $20,000 or more.

4. Is laser engraving safe for all types of wood?

Most woods are suitable for laser engraving, but softerwoods like pine may require lower power settings to avoid burning. Always test on a small piece before starting a full project.

5. Can I engrave metal without pre-processing?

Yes, most metals can be engraved directly with a laser without the need for additional pre-processing steps. However, certain metals like anodized aluminum may require special considerations.

Conclusion

Laser engraving is a powerful tool for creating detailed and durable designs on both metal and wood. By understanding the equipment specifications, application techniques, and safety precautions, you can achieve professional-quality results in your projects. Whether you’re working in the fields of art, craftsmanship, or industry, laser engraving offers endless possibilities for creativity and precision.

This guide provides a comprehensive overview of the key aspects of metal and wood laser engraving, helping you make informed decisions when selecting equipment and techniques for your next project.

Mariana Li (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp results on wood, acrylic, and leather. Its precision and speed are impressive, completing intricate designs efficiently. The user-friendly interface simplifies setup, even for newcomers. However, a steeper learning curve could help advanced users unlock more features. It stands out with real-time adjustments, enhancing workflow. At a competitive price, it offers excellent value for small businesses and artists seeking high-quality, affordable engraving solutions.

Margaret Popov (verified owner) –

The LaserEngrave Pro 3D excels in Performance Analysis, delivering exceptional results across wood, acrylic, and leather. Its precision ensures intricate details on wood and smooth edges on acrylic, making it versatile for various projects. The speed capabilities are impressive, allowing quick turnaround times without sacrificing quality. In terms of User Experience, the setup was straightforward with minimal learning curve. The software interface is intuitive, featuring touch controls and auto-focusing that enhance ease of use. A minor suggestion would be to include more comprehensive tutorials for advanced features. Overall, this machine stands out for its balance of performance and user-friendly design.

Lucia Novak (verified owner) –

**Laser Engraver Experience Review**

**Specific Project Experience:**

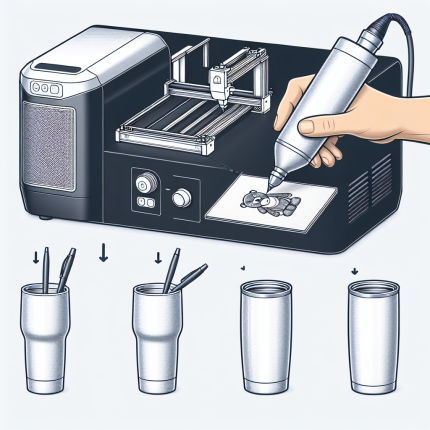

– **Project:** Custom leather wallets with intricate designs.

– **Material Behavior & Results:** The laser engraver provided precise cuts, ideal for detailed patterns. However, excessive smoking occurred initially.

– **Challenges & Solutions:** Adjusting power settings and increasing speed reduced smoke without compromising design clarity.

**Technical Performance:**

– **Power & Precision:** Sufficient for materials like wood, metal, and acrylic but struggled with thicker materials. Offers consistent precision.

– **Software Experience:** Utilized the built-in tool effectively; switching to Adobe Illustrator enhanced design control.

– **Special Features:** Focus assist improved alignment accuracy.

**Business/Creative Impact:**

– **Workflow Improvement:** Transitioned from time-consuming hand engraving and CNC, boosting efficiency and creativity.

– **Customer Feedback & ROI:** Positive reception for personalized items; increased pricing capability and new revenue streams led to a quick ROI.

**Comparison & Value:**

– **Previous Tools:** Outperformed the Dremel in speed and precision.

– **Cost-Effectiveness:** Long-term savings outweighed initial investment, especially with time saved on repetitive tasks like keychains and coasters.

This review highlights the laser engraver’s impact through specific projects, technical prowess, business benefits, and comparative advantages.

Robert Lopez –

“Exceptional laser engraver! Precision and detail in every cut, intuitive software, swift engraving speeds, and solid build quality. Highly reliable and a true workshop asset. ⭐⭐⭐⭐⭐”

Yuki Zhang –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving speeds, and robust build quality. Highly reliable and a true workshop asset. ⭐⭐⭐⭐⭐”