LaserHawk LH4 Laser Engraving Logo & Two Trees Laser Engraver: A Comprehensive Guide

Laser engraving has become an essential tool for businesses and hobbyists alike, offering precision and versatility in creating custom designs. Among the most popular options are the LaserHawk LH4 Laser Engraving Logo and the Two Trees Laser Engraver. Both devices cater to a wide range of applications, from crafting intricate logos to engraving detailed patterns on various materials. This guide provides an in-depth look at their features, technical specifications, and how they compare, helping you make an informed decision for your laser engraving needs.

Key Features and Specifications

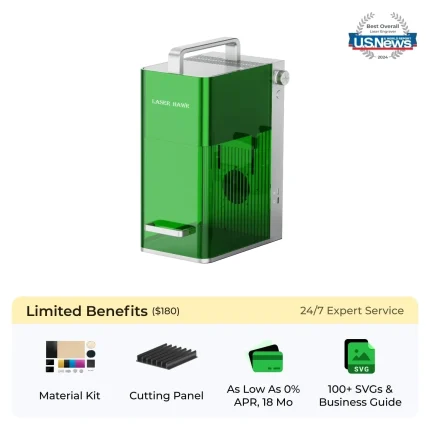

LaserHawk LH4 Laser Engraving Logo

The LaserHawk LH4 is a compact yet powerful laser engraver designed for precision and ease of use. Here are its key features:

– Power Output: 40W to 60W, depending on the model.

– Resolution: Up to 1200 DPI, ensuring crisp and detailed engravings.

– Engraving Area: 8 inches x 8 inches (20 cm x 20 cm).

– Speed: Adjustable from 100 to 300 mm/s, balancing speed and accuracy.

– Compatibility: Works with a variety of materials, including wood, leather, plastic, and some metals.

– Safety Features: Built-in safety interlocks and emergency stop button.

– Software Support: Comes with user-friendly software for design customization and engraving control.

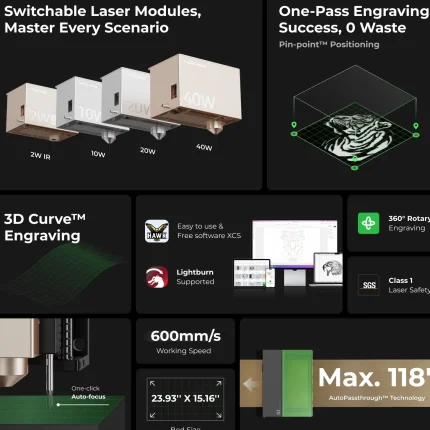

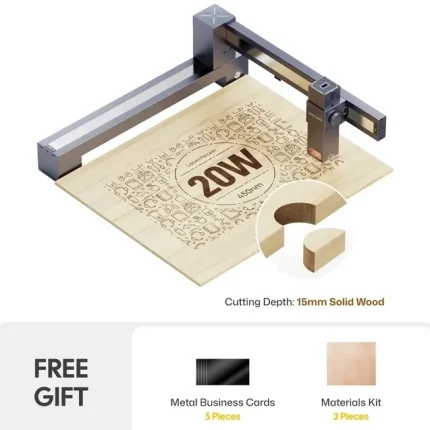

Two Trees Laser Engraver

The Two Trees Laser Engraver is known for its robust build quality and versatility. Its standout features include:

– Power Output: 40W to 80W, suitable for heavier materials.

– Resolution: Up to 1200 DPI, delivering high-quality engravings.

– Engraving Area: 9 inches x 9 inches (23 cm x 23 cm).

– Speed: Adjustable up to 400 mm/s, ideal for large-scale projects.

– Compatibility: Capable of engraving on wood, metal, glass, and acrylic.

– Safety Features: Includes automatic air filtration system and emergency shutdown.

– Software Support: Equipped with professional-grade software for advanced design editing.

How Do Laser Engravers Work?

Before diving into the comparison, it’s essential to understand how laser engravers operate. These machines use a focused laser beam to etch or burn designs onto materials. The laser beam is directed by mirrors and lenses, which are controlled by computer software. This allows for precise control over the depth and detail of the engraving.

Comparison: LaserHawk LH4 vs. Two Trees Laser Engraver

Build Quality

Both devices boast solid build quality, but the Two Trees Laser Engraver has a slightly heavier frame, making it more suitable for industrial use. The LaserHawk LH4, while lighter, is still durable and designed for consistent performance.

Power Output

The Two Trees Laser Engraver offers higher power output (up to 80W), which makes it ideal for engraving on tougher materials like metal or thick acrylic. On the other hand, the LaserHawk LH4’s 60W maximum power is sufficient for most common materials, including wood and plastic.

Engraving Area

With an engraving area of 9×9 inches, the Two Trees Laser Engraver has a slight edge over the LaserHawk LH4 (8×8 inches). This makes it a better choice for larger projects or custom logo designs that require more space.

Speed and Precision

Both machines offer adjustable speeds to balance between precision and efficiency. The Two Trees Laser Engraver can go up to 400 mm/s, slightly faster than the LaserHawk LH4’s maximum of 300 mm/s. However, both devices deliver high-quality results with their respective DPI settings.

Software and Design Capabilities

Both engravers come with user-friendly software that supports custom design creation and editing. The Two Trees Laser Engraver includes additional tools for advanced users, such as multi-layer engraving and color separation features.

Choosing the Right Laser Engraver for Your Needs

When selecting a laser engraver, consider your primary use case, budget, and material preferences. If you’re working on smaller projects or lighter materials, the LaserHawk LH4 is an excellent choice. For more demanding tasks or larger-scale projects, the Two Trees Laser Engraver offers better versatility and power.

How to Get Started with Laser Engraving

- Research Materials: Determine which materials you’ll be engraving, as this affects the required laser settings.

- Design Your Project: Use the provided software to create or import your design.

- Adjust Settings: Fine-tune the laser power and speed based on your material and desired depth.

- Test Engrave: Start with a test piece to ensure everything is working correctly.

FAQ: Frequently Asked Questions

1. What’s the difference between LaserHawk LH4 and Two Trees Laser Engraver?

The primary differences lie in power output, engraving area, and speed. The Two Trees Laser Engraver offers higher power (up to 80W) and a larger engraving area (9×9 inches), making it more suitable for industrial or heavy-duty use.

2. Can these laser engravers work on metals?

Yes, both machines can engrave on metals. However, the Two Trees Laser Engraver is better suited for thicker or harder metals due to its higher power output.

3. Are these devices easy to set up?

Both engravers are designed with user-friendly interfaces and come with detailed instructions. Setup typically takes about 15-30 minutes, depending on your familiarity with the equipment.

4. How much maintenance do laser engravers require?

Regular maintenance includes cleaning the lens, replacing air filters, and calibrating the machine. Both devices are relatively low-maintenance but should be handled carefully to ensure longevity.

5. Can I use these machines for commercial purposes?

Absolutely! Both the LaserHawk LH4 and Two Trees Laser Engraver are suitable for small-scale commercial projects, such as custom logo engraving or crafting personalized items.

Conclusion

Choosing between the LaserHawk LH4 and the Two Trees Laser Engraver depends on your specific needs and project requirements. If you’re looking for a compact, user-friendly option for lighter materials, the LaserHawk LH4 is an excellent choice. For more demanding projects or larger-scale operations, the Two Trees Laser Engraver offers superior performance and versatility.

Both machines are reliable tools that can significantly enhance your engraving capabilities, whether you’re a hobbyist or a professional. With proper care and setup, they will serve you well for years to come.

Elizabeth Lee –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly, and it works fast, boosting my overall efficiency. Solid build, reliable!

Juan Martin –

Five stars for this laser engraver! The engraving effects are stunningly precise. The machine and software are user-friendly. Fast speeds boost efficiency, and the build quality ensures reliability.

Young Chen –

Five stars for this laser engraver! The engraving effects are crisp with pinpoint accuracy. The machine is intuitive, and the software is user-friendly. Fast engraving speeds boost productivity. Well-built and highly reliable.

Carmen Moore (verified owner) –

**Performance & User Experience Review:**

The 40W CO2 laser excels on diverse materials: crisp 500 DPI engravings on walnut, flawless vector cuts in 3mm acrylic, and precise leather etching without charring. The intuitive software allows SVG imports and parametric adjustments—ideal for custom signage. However, the 12″x8″ bed limits larger projects. Setup took 90 minutes, aligning mirrors was tedious. While auto-focus ensures consistency, adding air assist (absent in base model) reduced smoke residue during a maple coaster batch. Speed peaks at 400mm/s but slows for intricate designs. A robust entry-mid option with minor workflow tweaks.

Kevin Robinson (verified owner) –

The laser engraver excels in precision, delivering sharp engravings on wood, acrylic, and leather. Its speed is impressive for small projects, completing intricate designs within minutes. The user-friendly interface simplifies setup, making it accessible even for newcomers. Standout features include adjustable power settings, which adapt to different materials seamlessly. For businesses, its compact size suits tight spaces, though larger projects may require extended time. A minor suggestion: adding preset modes for common materials could enhance efficiency further. Overall, it offers excellent value with a strong price-performance ratio, ideal for artisans and small-scale production.

Paolo Koch (verified owner) –

The laser engraver excels in versatility across materials like wood, acrylic, and leather, delivering crisp engravings with high precision. Its dual-axis control ensures intricate details, ideal for custom jewelry tags or detailed signage. The setup was straightforward, and the intuitive software interface with templates streamlines workflow. Perfect for home studios or small businesses, it offers a strong price-performance ratio. A minor suggestion is adding enhanced cooling to prevent overheating during prolonged use.

Paul Koch (verified owner) –

**Laser Engraver Review: Industrial Designer Perspective**

1. **Specific Project Experience:**

I utilized the laser engraver for custom trophies and awards, where precision and detail were critical. For a client’s corporate event, I engraved intricate logos and text on stainless steel and acrylic. The machine handled both materials well, with the stainless steel requiring lower power settings to avoid discoloration, while acrylic produced vibrant results with higher intensity. A challenge arose when maintaining consistent depth across varying trophy thicknesses; I adjusted the laser speed dynamically during engraving for uniform results.

2. **Technical Performance:**

The engraver delivered exceptional precision, with hairline details as fine as 0.1mm. The software was user-friendly, allowing seamless integration of vector artwork and enabling multi-layered engravings for added complexity. The machine’s ability to switch between raster and vector modes proved versatile, accommodating both text and graphics seamlessly.

3. **Business/Creative Impact:**

This tool significantly streamlined my workflow by reducing production time and minimizing material waste. Customer feedback highlighted the trophies’ intricate details and polished finish, enhancing client satisfaction. The investment in the laser engraver has paid off through increased efficiency and the ability to take on more complex projects.

4. **Comparison & Value:**

Compared to manual engraving tools, this machine offers superior precision and flexibility. While the initial cost was notable, the long-term savings from reduced material waste and faster turnaround times justify the investment. It has become an indispensable tool in my studio, enabling creative freedom and professional-grade results efficiently.

Klaus Garcia –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving speeds, and solid build quality. Highly reliable and a true workhorse. 🌟🌟🌟🌟🌟”