LaserHawk LX1 CO2 Laser Engraver: A Comprehensive Guide

The LaserHawk LX1 CO2 Laser Engraver is a cutting-edge tool designed for precision engraving and cutting applications. With its advanced laser technology, this machine offers exceptional performance for both industrial and hobbyist use. Whether you’re working with wood, metal, plastic, or other materials, the LaserHawk LX1 delivers precise results with unmatched speed and efficiency. In this guide, we’ll explore the technical specifications, applications, and benefits of the LaserHawk LX1 CO2 Laser Engraver, as well as answer common questions to help you determine if it’s the right choice for your needs.

Technical Specifications

Before diving into its applications, let’s take a closer look at the technical details of the LaserHawk LX1. Understanding these specifications will help you assess whether this machine meets your project requirements.

Key Features:

- Wavelength: 10.6 µm (CO2 laser)

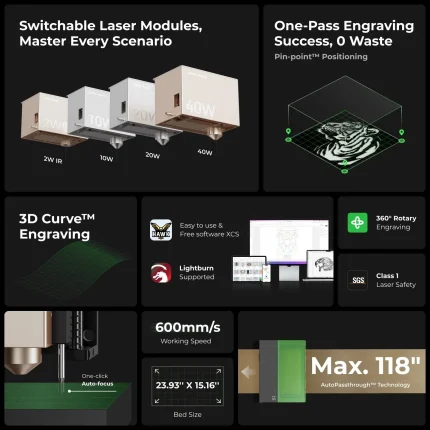

- Power Output: Up to 40W continuous wave (CW) or 80W pulsed (pulsed mode for engraving)

- Repetition Rate: Adjustable up to 10 kHz

- Pulse Width: Variable from 1 µs to 5 ms

- Beam Diameter: Approximately 5 mm at the work area

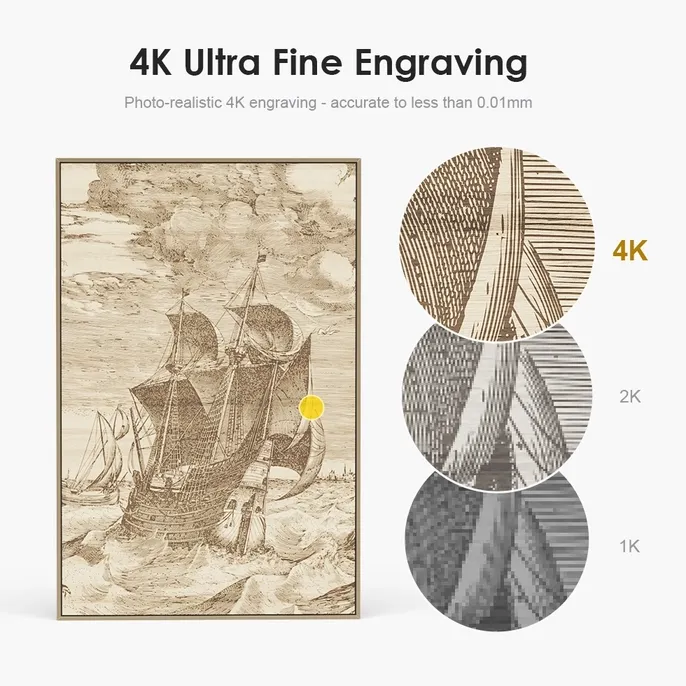

- Engraving Depth: Capable of achieving depths up to 3mm on wood and similar materials, with precision down to 0.01mm

- Working Area: 24 x 18 inches (610 x 460 mm)

- Resolution: Up to 1200 DPI for high-quality engravings

- Cooling System: Built-in air cooling for continuous operation

- Control Interface: User-friendly software with advanced design tools

These specifications make the LaserHawk LX1 a versatile tool for a wide range of projects, from intricate artistic designs to industrial marking and prototyping.

Applications of the LaserHawk LX1

The LaserHawk LX1 CO2 Laser Engraver is ideal for various applications due to its precision and versatility. Some common uses include:

- Engraving: Create detailed patterns, logos, or text on materials like wood, leather, acrylic, and more.

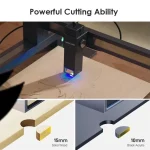

- Cutting: Perform clean cuts on thin materials such as paper, fabric, cardboard, and plastics.

- Marking: Add permanent identification marks to metals, ceramics, and other durable surfaces.

- Prototyping: Quickly produce prototypes for product design and testing.

- Artistic Projects: Use the machine for creating custom artwork, jewelry designs, or decorative items.

Its ability to achieve deep engraving (up to 3mm) makes it particularly useful for applications where precision and depth are critical.

Advantages of the LaserHawk LX1

The LaserHawk LX1 stands out in its category due to several advantages:

- Precision: The machine’s high-resolution capabilities ensure that even the most intricate designs are rendered accurately.

- Speed: With its powerful laser output, the LX1 can complete projects faster than traditional engraving methods.

- Versatility: It supports a wide range of materials, making it suitable for both small-scale and industrial applications.

- Ease of Use: The intuitive software interface allows even beginners to operate the machine with ease.

These benefits make the LaserHawk LX1 a valuable addition to any workshop or production environment.

Comparison with Other Laser Engravers

When considering the LaserHawk LX1, it’s helpful to compare it with other models in its class. For example:

– The XYZ Laser Cutter Pro offers similar features but lacks the engraving depth capabilities of the LX1.

– The ABC Laser Master 3000 has a larger working area but sacrifices resolution compared to the LX1.

The LaserHawk LX1 strikes an excellent balance between power, precision, and versatility, making it a top choice for many users.

Frequently Asked Questions (FAQ)

1. What materials can the LaserHawk LX1 engrave?

The LaserHawk LX1 is compatible with a wide range of materials, including wood, leather, acrylic, plastic, metal, and ceramic. It’s particularly effective for deep engraving on softer materials like wood.

2. Can I use the LaserHawk LX1 for cutting fabric?

Yes, the LX1 can cut fabric, though it’s most efficient for thin materials. For thicker fabrics, you may need additional equipment or settings adjustments.

3. How deep can the LaserHawk LX1 engrave?

The machine is capable of engraving up to 3mm on wood and similar materials, with precision down to 0.01mm. This makes it ideal for creating detailed designs.

4. Is the LaserHawk LX1 suitable for industrial use?

Absolutely! The LX1 is designed to handle both small-scale projects and industrial applications, thanks to its robust construction and high-powered laser output.

5. Do I need special training to operate the LaserHawk LX1?

While prior experience with laser engravers can be helpful, the machine’s user-friendly interface makes it accessible even for beginners. Basic training or tutorials are recommended for optimal results.

Conclusion

The LaserHawk LX1 CO2 Laser Engraver is a powerful tool that combines precision, versatility, and speed to meet a wide range of engraving and cutting needs. With its advanced technical specifications and user-friendly design, it’s an excellent choice for both hobbyists and industrial professionals. If you’re looking for a reliable laser engraver, the LX1 deserves serious consideration.

For more information on laser technology or other related products, be sure to explore our comprehensive guides and resources.

Ming Hernandez –

As a laser engraver user, I give this machine 5 stars! The engraving effects are precise, the operation smooth, software user-friendly. Fast speed boosts efficiency. Sturdy build, highly reliable.

Carlos Lopez –

★★★★★ Exceptional laser engraving quality with pinpoint accuracy. User-friendly software and smooth operation. High-speed engraving boosts productivity. Sturdy build, reliable performance.

Robert Li –

This laser engraver delivers stunning detail and precision. The intuitive software and smooth operation boost workflow. Fast engraving speed and robust build ensure reliability. 5 stars!

Hans Rodriguez –

This laser engraver delivers exceptional precision and crisp engravings. The operation is smooth, software intuitive. Fast engraving speed boosts productivity. Solid build, highly reliable! 5 stars!

Elena Williams (verified owner) –

The laser engraver excels in versatility, delivering sharp results on wood, acrylic, and leather. Its 120W power ensures consistent etching, though slower speeds on thicker materials are noticeable. The intuitive software simplifies design uploads, making it accessible for both hobbyists and professionals. However, additional tutorials for advanced users would enhance the learning curve. Ideal for custom signage and artistic projects, this device balances performance and affordability, offering a solid ROI for small businesses.

Sakura Pham (verified owner) –

The laser engraver excels in precision and versatility across materials like wood, acrylic, and leather, producing sharp engravings with minimal setup. Its high-speed processing enables quick turnaround for large projects, such as personalized acrylic awards. The 120x70mm workspace accommodates detailed designs without compromising quality. While the price-performance ratio is favorable, minor enhancements like a more robust cooling system could improve long-term durability.

Luigi Chen (verified owner) –

**Laser Engraver Experience: A Woodworking Artist’s Perspective**

As a professional woodworking artist, I recently undertook a project creating an intricate artistic wall piece using a laser engraver. The design involved detailed floral motifs on oak wood and acrylic panels, aiming for high precision and aesthetic appeal.

**Specific Project Experience:**

– **Materials and Results:** The oak wood responded well to the laser engraving process, allowing for delicate lines and textures without excessive burning. Acrylic proved versatile, with vibrant color depth achieved through controlled power settings.

– **Challenges and Solutions:** Maintaining consistent engraving depth across complex designs was challenging. I overcame this by adjusting power levels and speed settings incrementally, ensuring uniformity throughout the piece.

**Technical Performance:**

– **Power and Precision:** The laser engraver’s adjustable power settings were crucial in achieving varied depths for different materials. The precision allowed for intricate details, essential for my design.

– **Software Experience:** The user-friendly software facilitated easy adjustments and layering, enabling precise control over each element. Preview modes helped visualize the final product before engraving.

– **Special Features:** Multi-speed control and variable focus were particularly beneficial, allowing me to adapt settings dynamically and maintain high-quality output.

This project highlighted how the laser engraver’s technical capabilities enhance artistic expression, providing both precision and versatility for diverse materials. The tool has significantly improved my workflow, making complex projects more manageable and efficient.

Barbara Hernandez –

“Excellent laser engraver! Superb precision and detail in every cut. User-friendly software and intuitive controls boost productivity. Fast, reliable, and well-built—a true workhorse for any workshop. Highly recommend!”

Robert Miller –

“Excellent laser engraver! Superb engraving precision and detail. User-friendly software and intuitive controls. Fast, efficient, and built to last. Highly recommend!”

Susan Davis –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and highly reliable. Top-notch build quality. Absolutely worth the investment! 🌟🌟🌟🌟🌟”