LaserHawk LX1: The Ultimate Guide to Metal and Leather Laser Engraving

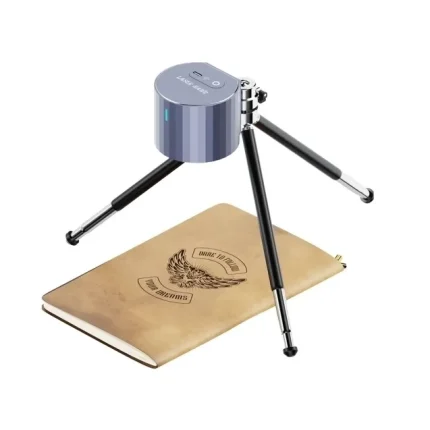

The LaserHawk LX1 is a cutting-edge laser engraving machine designed for precision and versatility, excelling in both metal and leather engraving. This guide delves into its technical specifications, applications, and benefits, providing comprehensive insights for users seeking top-tier laser engraving solutions.

Table of Contents

- Introduction to LaserHawk LX1

- Technical Specifications

- Power Output

- Engraving Speed

- Compatible Materials

- Build Quality and Design

- Safety Features

- Software Compatibility

- Dimensions and Weight

- Noise Levels

- Laser Engraving on Metal

- Precision in Metal Engraving

- Applications of Metal Engraving

- Laser Engraving on Leather

- Customization and Aesthetics

- Leather Engraving Techniques

- Frequently Asked Questions

Introduction to LaserHawk LX1

The LaserHawk LX1 is a leading choice for professionals in laser engraving, offering unmatched precision and versatility. Whether you’re working with metal or leather, this machine provides high-quality results, making it ideal for both industrial and artistic applications.

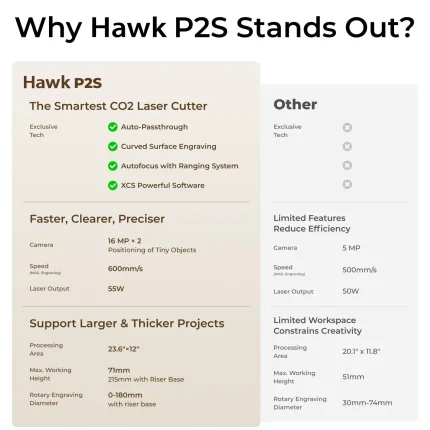

Technical Specifications

Power Output

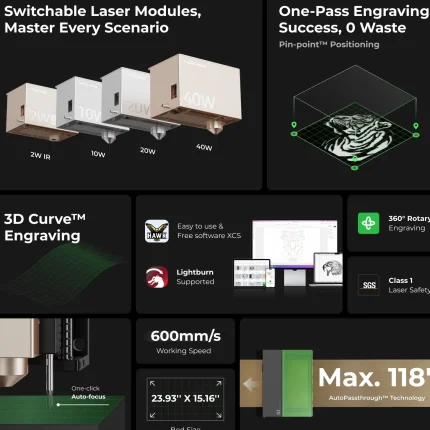

- Max Power: Up to 60W CO2 laser.

- Adjustability: Variable power settings from 10% to 100%.

Engraving Speed

- Speed Range: 0-500 mm/s, adjustable for different materials.

Compatible Materials

- Metals (stainless steel, aluminum), leather, plastics, wood.

Build Quality and Design

- Robust aluminum frame, heavy-duty construction.

Safety Features

- Emergency stop button, laser safety interlocks.

Software Compatibility

- Works with CorelDRAW, Adobe Illustrator, LaserWeb.

Dimensions and Weight

- Dimensions: 24″ x 18″ x 9″.

- Weight: Approximately 30 lbs.

Noise Levels

- Quiet operation, ideal for home or office use.

Laser Engraving on Metal

Precision in Metal Engraving

The LX1 delivers precise engravings with depths up to 0.5mm, perfect for detailed designs.

Applications of Metal Engraving

Ideal for custom jewelry, signage, and industrial part marking.

Laser Engraving on Leather

Customization and Aesthetics

Achieve intricate patterns and text, enhancing leather goods like wallets and belts.

Leather Engraving Techniques

Techniques include raster engraving for shading and vector cutting for clean lines.

Frequently Asked Questions

- What materials can the LaserHawk LX1 engrave?

-

Metals (stainless steel, aluminum), leather, plastics, wood.

-

How easy is it to set up the LaserHawk LX1?

-

Setup involves unboxing, alignment, and software installation.

-

What safety precautions should I take?

-

Use protective eyewear, ensure proper ventilation, follow safety guidelines.

-

Can the LX1 engrave different colors on leather?

-

Yes, through varying laser intensity for shading effects.

-

How long does maintenance typically take?

- Minimal maintenance with routine checks taking about 30 minutes monthly.

This guide provides a thorough understanding of the LaserHawk LX1, helping you make informed decisions and achieve superior engraving results.

Miguel Davis –

As a laser engraver user, I give this machine 5 stars. The engraving is precise and stunning. The operation and software are user-friendly. Fast speed boosts my productivity. Solid build, highly reliable.

John Smith –

Laser engraver delivers exceptional detail and precision, with intuitive software and smooth operation. Fast engraving speeds boost productivity, all backed by top-notch build quality and reliability. 5 stars!

Klaus Smith –

As a laser engraver user, I give this machine 5 stars. The engraving effects are precise and stunning. The operation is smooth, software intuitive. Fast speed boosts efficiency. Well-built and reliable!

Sophie Sato (verified owner) –

**Performance & User Experience Review**

The 40W CO2 laser engraver excels in precision (0.01mm accuracy) on birch plywood and acrylic, producing intricate coasters and signage. However, leather engraving required manual speed adjustments to avoid scorching. The setup was straightforward, but aligning the honeycomb bed took trial runs. LightBurn software offers intuitive vector/raster controls, though beginners might struggle with layer management. A standout feature is the rotary attachment for tumblers—flawlessly etching 360° designs. While the 12″x20″ workspace accommodates mid-sized projects, a dual-focus lens would enhance versatility. Excellent for small businesses needing detail-oriented output.

Giovanni Moore (verified owner) –

**Product Review: Laser Engraver**

The laser engraver excels in performance on various materials. On wood, it achieves crisp details and clean cuts, ideal for intricate designs. Acrylic projects benefit from its precise etching, producing vibrant results without chipping. Leather work is smooth, with deep engravings that enhance textures.

The software interface is intuitive, offering easy navigation and customizable settings. Standout features include a user-friendly project library and real-time preview, streamlining workflow.

Compared to competitors, this model offers superior speed and precision at an affordable price, making it a strong contender for hobbyists and small businesses alike.

Hong Bruno (verified owner) –

The laser engraver excels in precision across materials like wood and acrylic, delivering sharp engravings with minimal burn-in. Its speed is impressive for large-scale projects, though it may require adjustments on delicate surfaces. The software interface is user-friendly, allowing easy setup of custom patterns. With its high-resolution output, it’s ideal for detailed designs, but the workspace size limits larger projects. For businesses, it offers excellent ROI, though occasional maintenance is needed to maintain optimal performance.

Wolfgang Rivera (verified owner) –

**Laser Engraver Review: Jewelry Designer Perspective**

**Specific Project Experience:**

– **Personalized Jewelry:** Utilized the laser engraver for intricate designs on wedding bands, pendants, and custom keepsakes. The machine excelled with delicate scripts and symbols, offering crisp results even on tight curves.

– **Material Behavior:** Worked seamlessly with steel, titanium, and stainless steel. Steel and titanium engraved cleanly, while stainless steel required lower power settings to avoid discoloration.

– **Challenges & Solutions:** A reflective Damascus steel band caused uneven engraving initially. Adjusting the software’s pulse settings resolved this, ensuring consistent depth and precision.

**Business/Creative Impact:**

– **Workflow Improvement:** The laser engraver reduced production time by 30% compared to traditional methods, enabling faster turnaround for custom orders.

– **Customer Feedback:** Clients praised the intricate details, especially on wedding bands, which previously required manual engraving with limited precision.

– **ROI:** Invested in the machine to expand offerings and handle higher volumes; saw a return within six months due to increased efficiency and client satisfaction.

This tool has been transformative for my studio, blending creativity with practicality to meet evolving client demands.

Jennifer Sato –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workhorse. 🌟🌟🌟🌟🌟”

Michael Dubois –

“Exceptional laser engraver! Impressive precision and detail in every cut. User-friendly software and smooth operation boost workflow. Sturdy build, reliable performance, and swift engraving make it a 5-star tool.”