Wood Laser Engraving Machine: A Comprehensive Guide to Affordable Laser Engravers

Wood laser engraving machines have revolutionized the way we create intricate designs and patterns on wood. These devices are ideal for hobbyists, crafters, and professionals alike, offering precision and efficiency in carving detailed designs. In this guide, we will explore everything you need to know about affordable wood laser engraving machines, including their technical specifications, benefits, and how to choose the right one for your projects.

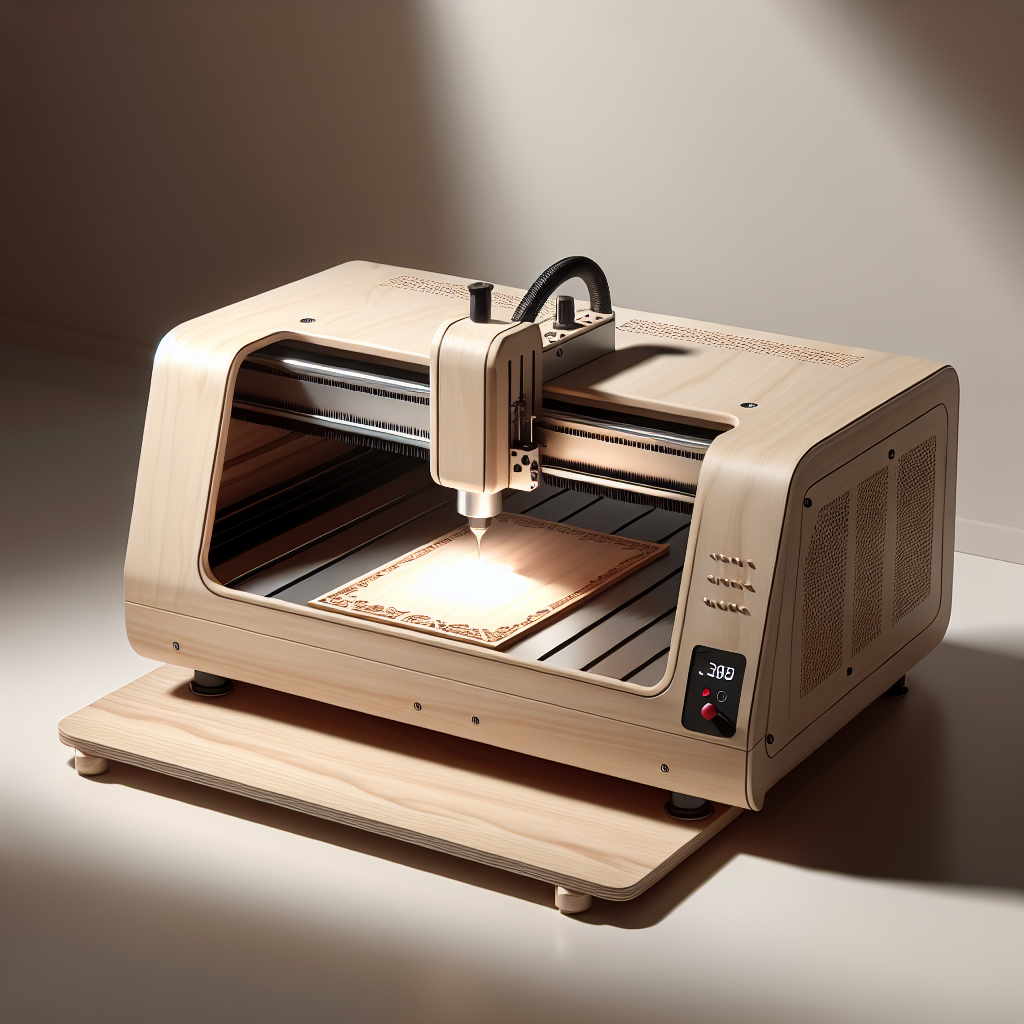

What is a Wood Laser Engraving Machine?

A wood laser engraving machine uses a focused beam of light (laser) to etch or cut designs onto wooden surfaces. Unlike traditional carving tools, these machines offer unparalleled precision and consistency. They are perfect for creating custom furniture, decorative items, signage, and personalized gifts. Affordable laser engravers have made this technology accessible to a broader audience, enabling even small-scale crafters to produce high-quality work.

Technical Specifications of Wood Laser Engraving Machines

Understanding the technical specifications is crucial when selecting a wood laser engraving machine. Below are some key features to consider:

- Laser Type: Most affordable wood laser engravers use CO2 lasers, which are ideal for cutting and engraving non-metallic materials like wood, acrylic, and leather.

- Power Output: The power of the laser (measured in watts) determines its capability to cut through different materials. Higher wattage lasers can handle thicker wood and faster processing speeds.

- Build Quality: Look for machines with durable construction, including solid frames and high-quality components to ensure longevity and performance.

- Software Compatibility: Many affordable laser engravers come with user-friendly software that allows you to design and edit patterns before engraving. Some also support popular CAD programs.

- Safety Features: Ensure the machine includes safety features like emergency stop buttons, smoke extraction systems, and enclosed laser chambers to protect users from hazards.

- Operating System: Check if the machine is compatible with your computer’s operating system (Windows or macOS).

Benefits of Using a Wood Laser Engraving Machine

- Precision and Accuracy: Laser engraving machines can create intricate designs with extreme precision, ensuring every detail is captured perfectly.

- Speed: Compared to manual carving, laser engraving is significantly faster, making it ideal for large-scale projects or high-volume production.

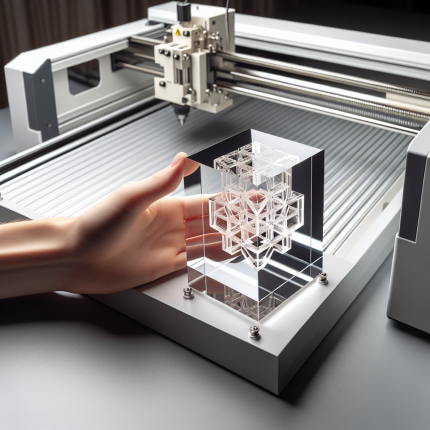

- Versatility: These machines can handle various materials beyond wood, including acrylic, leather, and even some types of metal.

- Cost-Effective: While the upfront cost of an affordable laser engraver may seem daunting, it is a long-term investment that can save time and resources compared to traditional methods.

Choosing the Right Wood Laser Engraving Machine

When selecting a wood laser engraving machine, consider your project requirements, budget, and skill level. Here are some factors to keep in mind:

1. Project Size

Determine the size of the projects you plan to undertake. Smaller machines may be sufficient for hobbyists, while larger ones are better suited for industrial or commercial use.

2. Budget

Affordable laser engravers come at varying price points. Set a budget and look for models that offer the best balance of features and performance within your range.

3. Ease of Use

If you’re new to laser engraving, opt for machines with intuitive controls and user-friendly software. Many affordable options come with pre-designed templates to simplify the learning curve.

4. Maintenance

Laser engravers require regular maintenance to ensure optimal performance. Look for models that are easy to clean and have replaceable parts readily available.

Maintaining Your Wood Laser Engraving Machine

Proper maintenance is essential to extend the lifespan of your wood laser engraving machine and maintain its performance. Here are some tips:

- Clean Regularly: Dust and debris can accumulate inside the machine, affecting its functionality. Clean it after each use using a soft cloth or compressed air.

- Check Laser Lens: The laser lens is critical for focusing the beam accurately. Inspect it regularly and replace if necessary.

- Update Software: Keep the software up to date to ensure compatibility with new features and improved performance.

Frequently Asked Questions (FAQs)

1. How much does a wood laser engraving machine cost?

The cost of an affordable wood laser engraving machine can range from $500 to $3,000, depending on the brand, features, and size. Entry-level models are often priced around $800-$1,200, making them accessible for hobbyists and small-scale crafters.

2. Can I use a wood laser engraving machine for small-scale projects?

Absolutely! Many affordable laser engravers are compact and designed specifically for small to medium-sized projects. They are perfect for creating personalized gifts, decorative items, and custom furniture details.

3. What materials can I engrave besides wood?

In addition to wood, wood laser engraving machines can work with a variety of materials, including acrylic, leather, glass, and some types of metal. However, ensure the machine is compatible with the material you plan to use.

4. How difficult is it to learn how to use a laser engraving machine?

Most affordable laser engravers come with user-friendly software that simplifies the learning process. With practice, even beginners can create beautiful designs in no time.

5. Do I need special safety gear when using a laser engraving machine?

Yes, it’s important to wear appropriate safety gear such as goggles and gloves when operating a laser engraving machine. Additionally, ensure the machine is used in a well-ventilated area to avoid inhaling fumes from the engraving process.

Conclusion

Wood laser engraving machines have become an indispensable tool for anyone looking to create precise and detailed designs on wood. With advancements in technology, affordable laser engravers are now more accessible than ever, offering high-quality performance without breaking the bank. By understanding the technical specifications, benefits, and maintenance requirements of these machines, you can make an informed decision and start your journey into the world of laser engraving.

If you’re ready to take your woodworking projects to the next level, consider investing in a wood laser engraving machine. With its precision, versatility, and ease of use, it’s sure to become a valuable addition to your workshop.

Carol Baker (verified owner) –

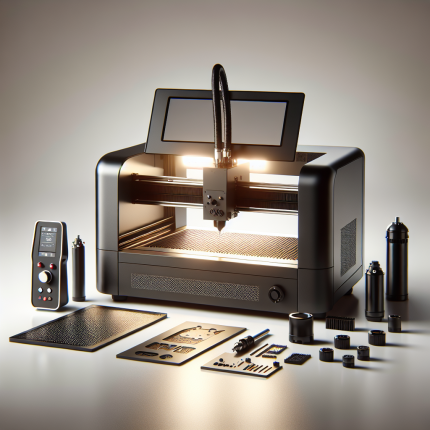

The laser engraver excels in precision and versatility across materials like wood, acrylic, and leather, delivering crisp engravings with minimal setup. The 40W laser offers sufficient power for deep cuts on wood and smooth etching on acrylic. Its user-friendly interface simplifies project management, though a steeper learning curve is needed for advanced features. For businesses, the ROI is strong due to its efficiency in producing high-quality custom items. However, adding an optional cooling system could enhance long-term durability. Overall, it’s a solid choice for hobbyists and small-scale operations seeking reliable performance at a reasonable price.

Thomas Zhang (verified owner) –

**Laser Engraver Experience for Custom Gift Shop**

**Introduction:**

Our custom gift shop recently integrated a laser engraver, significantly enhancing our product offerings and operational efficiency.

**Specific Project Experience:**

– **Example Project:** We created personalized cutting boards as wedding favors. The laser’s precision ensured intricate designs were etched beautifully into the wood.

– **Materials Used:** Acrylic, wood, glass, and some metals. Each material presented unique characteristics; acrylic required careful settings to avoid chipping, while wood needed temperature adjustments for clean engravings.

– **Challenges & Solutions:** Encountered inconsistent engraving on thick acrylic by adjusting power settings and using masking tape for delicate areas. Layering techniques enhanced depth in wooden engravings.

**Business/Creative Impact:**

– **Workflow Improvement:** The laser engraver streamlined our processes, reducing production time by 30% and allowing us to handle rush orders efficiently.

– **Customer Feedback:** Customers praised the quality and personalization, leading to increased repeat business and referrals.

– **ROI:** The investment was recouped within six months due to boosted sales and operational efficiency.

**Conclusion:**

The laser engraver has been a pivotal tool in our shop, enabling high-quality custom work that enhances customer satisfaction and drives business growth.

Anders Lopez –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably built. Highly recommend!”